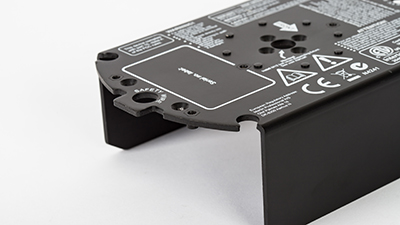

- [3C Electronics Industry]3C Electronics Industry09 Mar,2022

- At Mastars , our team of experts have worked alongside designers and engineers for decades to bring inventive, beautiful products into the hands of customers.An array of technologies and materials for every step of the product development life cycle allows you to bring your product to market faster than ever before.

- [Medical Device Industry]Solution for Medical and health parts06 Jan,2022

- The automotive industry represents a large part of the customer base and we believe to provide the highest quality solution for our customers. Our goal is to exceed your expectations and help you succeed in the market – this mission makes our customers trust.

- [Household Appliances Industry]Household Appliances Industry21 Dec,2021

- Mastars produced injection molds and tooling and decorative paint finishes for domestic and business-machine enclosures. Mastars's experience covers a wide range of domestic and commercial applications, from vacuum air to digital printers.

- [Automotive Industry]Automotive Industry21 Dec,2021

- The automotive industry represents a large part of the customer base and we believe to provide the highest quality solution for our customers. Our goal is to exceed your expectations and help you succeed in the market – this mission makes our customers trust.

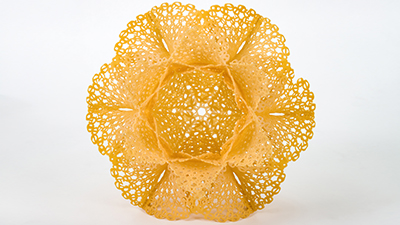

- [Cases]3D Printing: A Technological Revolution Restructuring Production Logic Across In17 Nov,2025

- 3D printing utilizes digital model-driven layer-by-layer deposition to break the geometric constraints and efficiency bottlenecks of traditional subtractive manufacturing, unleashing transformative value across dozens of fields including aerospace, healthcare, and automotive manufacturing.

- [Blog]Driving Innovation: The Transformative Role of Rapid Prototyping Tooling in the17 Nov,2025

- The article provides a detailed examination of specific technologies like Vacuum Casting, Direct Metal Laser Sintering (DMLS) for conformal-cooled molds, and sand casting for powertrain components.

- [Cases]3D Printing in the Rapid Prototyping of an Intake Manifold for New engine10 Nov,2025

- This case study provides a detailed analysis of how a leading automotive manufacturer (OEM) utilized additive manufacturing technology for the rapid prototyping of an intake manifold in a new high-performance turbocharged engine project.

- [Blog]The underlying logic of management: the SQDCM five priorities10 Nov,2025

- Today, we'll break down a proven logical hierarchy: security, quality, delivery, cost, and personnel/morale/maintenance. This isn't a random order; it's the underlying code for a company's long-term survival.

- [News]Vacuum Casting: Accelerating Innovation in the Automotive Industry with Mastars04 Nov,2025

- While technologies like 3D printing have revolutionized rapid prototyping, Vacuum Castingremains a cornerstone technology for producing high-quality, functional prototypes and small-batch components. This process is indispensable for bridging the gap between a digital design and mass production, especially within the automotive sector.

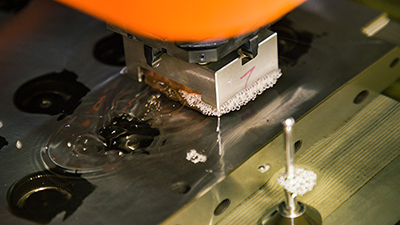

- [Blog]Precision at Pace: How Rapid CNC Machining is Powering Modern Innovation03 Nov,2025

- Rapid CNC Machining emerges as a critical manufacturing solution, bridging the gap between rapid prototyping and full-scale production. Mastars, providing professional Rapid CNC Prototyping services.

- [FAQ]The Ultimate 3D Printing Prototyping Terminology Glossary31 Oct,2025

- The list of terms and abbreviations in this glossary are commonly used in industry to refer to 3D printing or additive manufacturing forms or functions.

- [FAQ]3D Printing Prototyping: definition, process, advantages, applications31 Oct,2025

- Here's a detailed explanation of 3D Printing Prototyping, covering its definition, process, advantages, applications.Rapid prototyping with 3D printing is the process of quickly creating physical models from digital designs to test ideas and improve them faster

- [FAQ]The Glossary of Vacuum Casting Terminology31 Oct,2025

- Here is a detailed guide to the professional terminology associated with Vacuum Casting (also known as Urethane Casting or Polyurethane Casting)

- [FAQ]What Is Vacuum Casting? Definition, methods, process, comparison31 Oct,2025

- Vacuum Casting, also known as Polyurethane (PU) Casting or Urethane Casting, is an advanced manufacturing process used to produce high-quality, functional prototypes and end-use parts in small to medium volumes (typically 10-50 parts, but up to 100+). It is renowned for replicating the properties of injection-molded plastics without the high cost and lead time of production-grade tooling.