We can solve specific design or production challenges. If you want to explore how 3D printing can solve a specific design or production challenge our consultancy team is highly qualified to help. As engineers with over 20 years’ combined experience, we understand both the traditional manufacturing and additive manufacturing processes. We will advise you on how 3D printing can enhance the possibilities, quality and capabilities of your components, or make production more flexible and affordable.

The benefits using Mastars> Cuts costs and manufacturing lead times by removing the need for tooling > Supports agile manufacturing–parts can be made to order and modified if required > Reduces inventory – rapid production reduces the need for stock to be held > Reduces material and weight for previously solid parts by using lattice structures > Allows you to build more complex shapes so that parts comprise fewer components

The benefits using Mastars> Cuts costs and manufacturing lead times by removing the need for tooling > Supports agile manufacturing–parts can be made to order and modified if required > Reduces inventory – rapid production reduces the need for stock to be held > Reduces material and weight for previously solid parts by using lattice structures > Allows you to build more complex shapes so that parts comprise fewer components

Why work with us? > Advanced SLA, SLS, SLM 3D printing equipment > Medical, automotive, aerospace, industrial manufacturing, 3C electronics, mold manufacturing, many years of industry experience > Rich accumulation of rapid prototyping services for more than 20 years > Faster, higher quality and lower cost > The most advanced 5-axis CNC ensures the accuracy and quality of later processing

Why work with us? > Advanced SLA, SLS, SLM 3D printing equipment > Medical, automotive, aerospace, industrial manufacturing, 3C electronics, mold manufacturing, many years of industry experience > Rich accumulation of rapid prototyping services for more than 20 years > Faster, higher quality and lower cost > The most advanced 5-axis CNC ensures the accuracy and quality of later processing

SLS applications> Main material: resin > Concept creation and structure verification > Rapid prototyping > Automobile manufacturing > Consumer Electronics > Dental orthopedic > Industrial design models > architectural design > Sculptures > Culture creation periphery 01

SLS applications> Main material: resin > Concept creation and structure verification > Rapid prototyping > Automobile manufacturing > Consumer Electronics > Dental orthopedic > Industrial design models > architectural design > Sculptures > Culture creation periphery 01

SLA applications> Main material: resin > Concept creation and structure verification > Rapid prototyping > Automobile manufacturing > Consumer Electronics > Dental orthopedic > Industrial design models > architectural design > Sculptures > Culture creation periphery 02

SLA applications> Main material: resin > Concept creation and structure verification > Rapid prototyping > Automobile manufacturing > Consumer Electronics > Dental orthopedic > Industrial design models > architectural design > Sculptures > Culture creation periphery 02

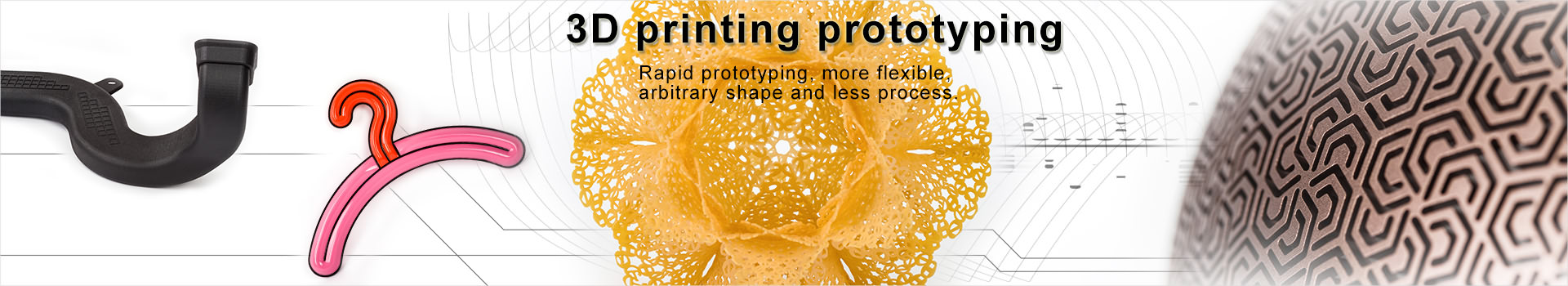

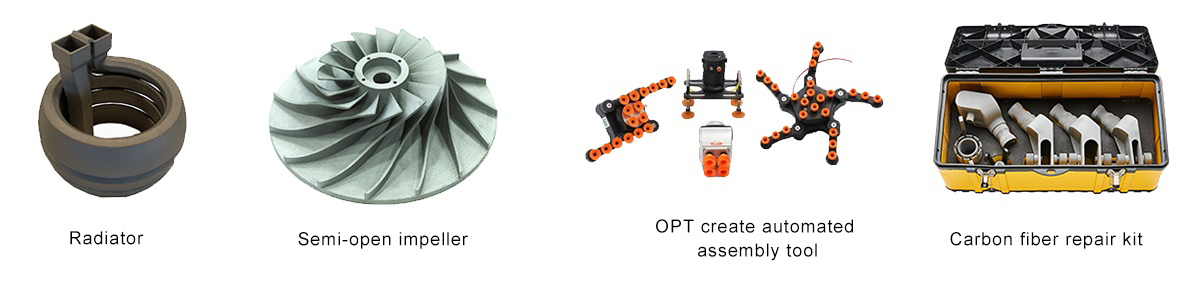

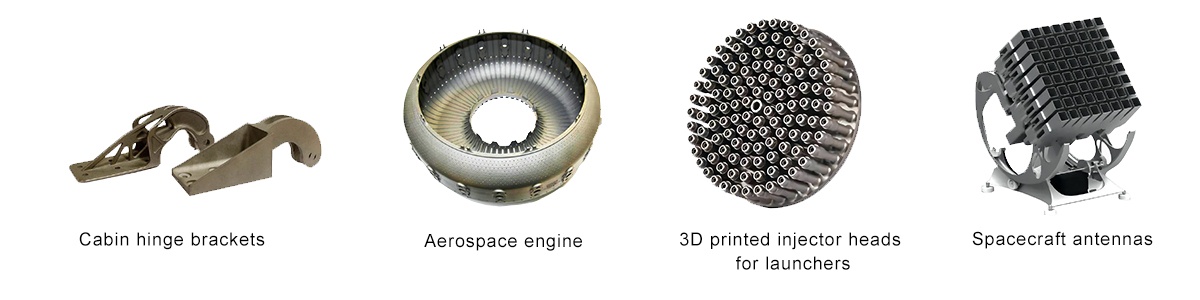

SLM applications > Main material: metal > Prototyping to mass production manufacturing > Produce products of any shape > Innovative lightweight components with cavity or honeycomb structures > MComplex and fast mold manufacturing > Conformal waterway of die > Automobile > Civil and military products > Energy and industry > Aerospace > Healthcare 03

SLM applications > Main material: metal > Prototyping to mass production manufacturing > Produce products of any shape > Innovative lightweight components with cavity or honeycomb structures > MComplex and fast mold manufacturing > Conformal waterway of die > Automobile > Civil and military products > Energy and industry > Aerospace > Healthcare 03

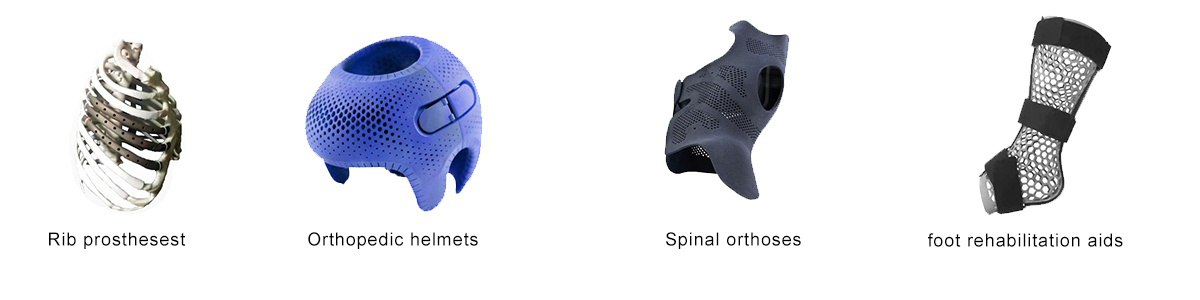

HP MJF applications> Main material: imported HP nylon > 10X faster than any other device currently on the market > Continuous printing and rapid cooling process > Lower cost > Prototyping to small batch products > Automobile manufacturing > Sports medical rehabilitation protection tools > Electronic appliances > Power tools > Professional sports equipment 04

HP MJF applications> Main material: imported HP nylon > 10X faster than any other device currently on the market > Continuous printing and rapid cooling process > Lower cost > Prototyping to small batch products > Automobile manufacturing > Sports medical rehabilitation protection tools > Electronic appliances > Power tools > Professional sports equipment 04

Solution: Auto parts have many surface structures, grid structures, prototypings and fixtures of parts, etc. It is very difficult to manufacture through mechanical processing, the manufacturing cost is expensive and the processing cycle is too long. 3D printing technology can directly make parts of any shape through computer graphics data, and the density of products produced by 3D printing technology can reach more than 99%. Now 3D printed auto parts have been partially mass-produced.

3D printing technology can not only greatly reduce the cost of automobile development and manufacturing, but also improve work efficiency and reduce the development time of new models and new parts. Ultimately, these will be reflected in the price and quality of the car, so better quality, better technology, and cheaper cars will emerge due to the popularity of 3D printing technology.

Solution: With the help of 3D scanning technology, precise data of individual patients can be obtained. Combined with the doctor's rehabilitation guidelines, 3D printing solutions including materials and craftsmanship can be provided. After that, rapid modeling and rapid manufacturing and delivery can provide patients with safe and beautiful personalized orthopaedic appliances in a timely manner.

Solution: Parts in industrial manufacturing have certain requirements for wear resistance, deformation resistance and durability. The progress of 3D printing materials has promoted the development of industrial manufacturing. It not only has the advantages of complex structural design and manufacturing, but also meets the requirements of practical applications in terms of the accuracy and physical properties of components, and even exceeds them. At the same time, the short processing cycle is its obvious advantage.

Solution: The 3C electronics industry has the characteristics of short life cycle of new products and fast update and iteration speed, so it is necessary to continuously develop and design new products. 3D printing has the advantages of mass production and rapid manufacturing of products with complex hierarchical structures, and can also provide customers with personalized customized services. In terms of time, it is obviously ahead of other processes, so in the prototyping verification and subsequent production, the cycle can be greatly shortened, so as to seize the market opportunity.

Solution: For a good mold, in addition to function, precision and product appearance, the most important thing is how to cool the mold quickly and evenly, so as to reduce the injection cycle of the mold and improve the quality of the product. .

The cooling time of mold injection is the key to demolding efficiency. The traditional mold cooling process cannot effectively control the mold temperature, resulting in uneven temperature inside the mold and causing product deformation problems. 3D printing technology can produce complex shapes and pipelines, that is, mold conformal cooling waterway can realize arbitrary shape cooling channel design, shortening the period of mold development and manufacturing costs.

Shorten production cycles: Save time and increase efficiency. A mold with a conformal waterway can effectively reduce the cooling cycle of the mold.

Solution: 3D printing technology has become a key technology to improve the design and manufacturing capacity of aerospace and spacecraft, and its application scope is constantly expanding, and shows the trend of expanding from parts to complete machine manufacturing. Significant benefits have been achieved in cost, cycle and weight, which fully shows the application prospect of 3D printing technology in this field.

Solution: 3D printing technology has replaced the traditional manual molding process, which has brought great improvement in the fineness and manufacturing efficiency of the work. It can be more direct and accurate in editing, magnifying, shrinking, original copy and other aspects of works, and achieve small batch production efficiently. For various complex shapes and material requirements, it can better meet the needs.

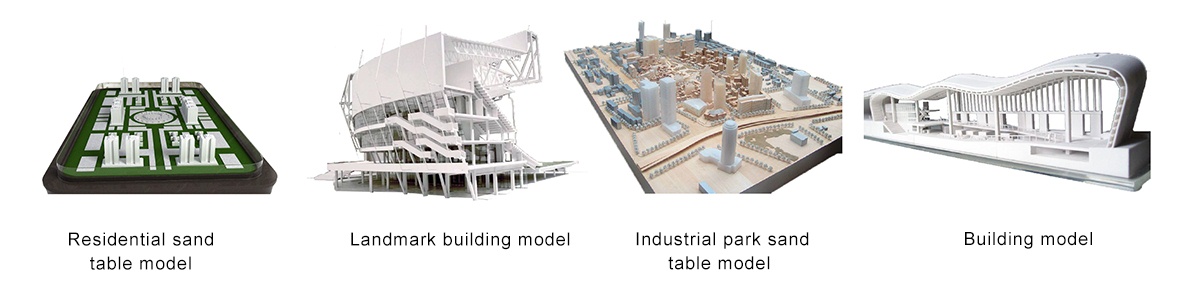

Solution: Architectural modeling is a way to visualize architectural plans. The traditional production method is time-consuming and labor-intensive and it is difficult to restore the reduced fine structure, and the production cost is expensive, which will give up important small details and cause negative effects. 3D printing effectively conveys design concepts in the form of miniature entities, and has simple operation, which can intuitively reflect the structure and size of buildings and other related characteristics.

Hybrid Prototyping: CNC and 3D Printing

Hybrid Prototyping: CNC and 3D Printing

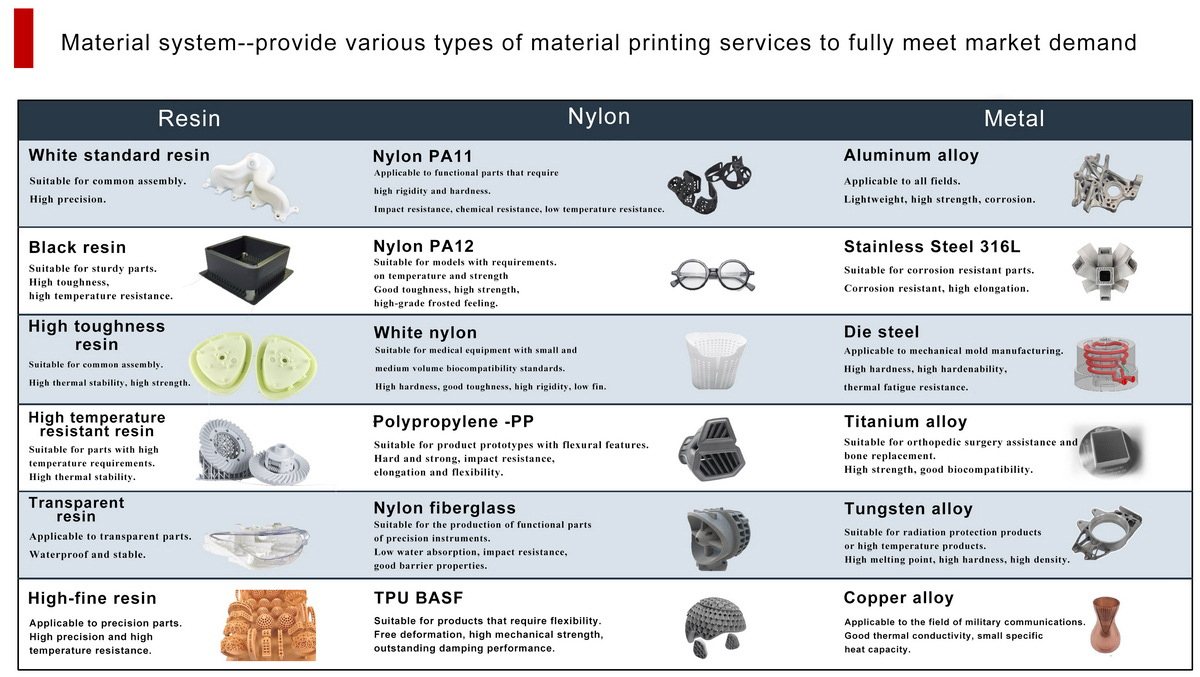

How to Choose the Right 3D Printing Material

How to Choose the Right 3D Printing Material

Metal 3D Printing Services: A New Option for High-Precision Manufacturing

Metal 3D Printing Services: A New Option for High-Precision Manufacturing

ORNL Combines 3D Printing and Thermal Isostatic Pressing to Manufacture Large Me

ORNL Combines 3D Printing and Thermal Isostatic Pressing to Manufacture Large Me