- [Household Appliances Industry]Household Appliances Industry21 Dec,2021

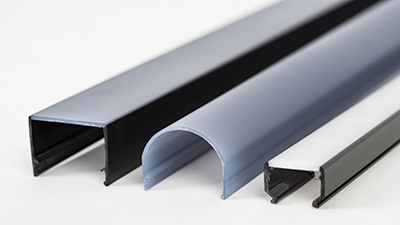

- Mastars produced injection molds and tooling and decorative paint finishes for domestic and business-machine enclosures. Mastars's experience covers a wide range of domestic and commercial applications, from vacuum air to digital printers.

- [Blog]DFM - Injection Molded Part Design07 Nov,2025

- The purpose of this chapter is to design parts that conform to plastic molding processes (i.e., injection molding) and avoid making simple mistakes.

- [Blog]Five Key Elements of Injection Molding – Injection Speed07 Nov,2025

- What is injection speed? Injection speed refers to the speed at which the screw moves forward during the injection phase, injecting molten plastic into the mold cavity. It is generally expressed in two ways: Screw travel speed: This ref...

- [Blog]Precision and Efficiency: The Dynamics of Modern Plastic Injection Molding03 Nov,2025

- Plastic injection molding stands as a cornerstone of modern manufacturing, enabling the mass production of high-precision, complex parts with remarkable efficiency. From everyday consumer goods to critical medical and automotive components, this process is vital for creating durable, repeatable, and cost-effective plastic products. At its core, injection molding is a highly technical discipline that blends material science, mechanical engineering, and precision machining.

- [FAQ]Metal Injection Molding (MIM): Professional Terminology31 Oct,2025

- Here is a detailed guide to the professional terminology associated with Metal Injection Molding (MIM). This glossary is organized to follow the sequential steps of the MIM process.

- [FAQ]Metal Injection Molding (MIM): A Detailed Overview31 Oct,2025

- Metal Injection Molding (MIM), also known as Powder Injection Molding (PIM), is an advanced manufacturing process that combines the design flexibility of plastic injection molding with the material performance of wrought metals.

- [FAQ]Glossary of Plastic Injection Molding Terms31 Oct,2025

- An A to Z guide to terminologies in Injection tooling.Here is a detailed English-language guide to the professional terminology associated with Injection Tooling (the mold). This glossary is organized by the function and location of components within the mold system.

- [FAQ]Terminology of the Injection Molding Industry31 Oct,2025

- Common Terms Within The Injection Molding Industry.Plastic injection molding is a manufacturing process wherein plastic is injected into aluminum, or steel molds and squeezed under high pressure to come up with the desired shape of the product

- [FAQ]A Beginner's Guide to Injection Molding31 Oct,2025

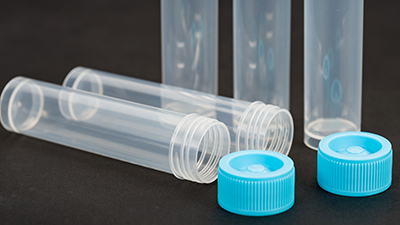

- Injection moulding is a manufacturing process that allows for parts to be produced in large volumes.

- [FAQ]Mastars: Detail Guide About Aluminum Injection Molding16 Mar,2022

- Prototypes or real products are produced by the aluminum injection molding technique. The aluminum tooling technique is used for the process of aluminum injection molding. It is the process based on the injection molding technique. Mastars is also a metal prototype maker.

- [Blog]Thermoset Injection Molding Process Explained18 Sep,2025

- Thermoset Injection Molding Process Explained Thermoset injection molding is a critical manufacturing process widely used in industries such as automotive, aerospace, consumer electronics, and medical devices. Unlike thermoplastics, thermos...

- [Blog]Why OEMs Use 3D Printing for Low-Volume Production16 Sep,2025

- Why OEMs Use 3D Printing for Low-Volume Production | Mastars Lower Tooling Costs Faster Lead Times Traditional methods like injection molding require expensive tooling and molds. For small batches or prototypes, the tooling cost alone can ...

- [FAQ]ABS Plastic Injection Molding Solutions|Mastars04 Sep,2025

- Mastars(provide rapid cnc services,rapid cnc machining,rapid prototyping services.)?When your business depends on plastic injection molded parts, Meiyu Tongrun is your best choice. We are an ISO 9001 certified manufacturer utilizing state-of-the-art 3D design, tool manufacturing, plastic injection molding and Robotics

- [Blog]Injection Molding Common Issues & Solutions23 Aug,2025

- Injection moulding defects like warping, sink marks, and short shots increase costs and risks. Solutions include precise machine adjustments, material selection, and advanced quality control tools for consistent, high-quality production.

- [Blog]Future Trends in the Injection Molding Industry: Digitization and Sustainability12 Aug,2025

- The injection molding industry's transformation is driven by digitization (IoT, AI, digital twins) and sustainability (eco-materials, energy efficiency). Challenges include costs and skills, while opportunities involve market growth and innovation. The convergence enhances efficiency and eco-friendliness.

- [News]FSD (Fully Self-Driving) Comes to China, Europe and Other Countries16 Oct,2024

- Tesla CEO Elon Musk announced in July that FSD will be available in China. The FSD feature is expected to launch in the Chinese market in the first quarter of 2025.

- [News]Automotive Speed-Warning Devices , Choice or Necessity?23 Sep,2024

- All new vehicles in the European Union need to have speed-warning devices. California is getting ready to do the same.