Body lightweighting has been an important issue for vehicle manufacturers to implement. Under the same weight, high strength steel can largely enhance the body strength and improve the crash safety performance. However, high-strength steel is difficult to form and has serious rebound, which leads to high difficulty in manufacturing and debugging of tooling. The emergence of thermoforming steel has perfectly solved the above two problems. The composition, properties and manufacturing process of thermoforming steel for automobiles are introduced as follows.

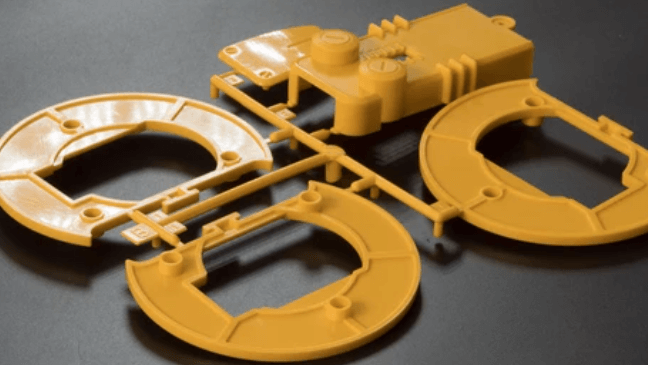

The main parts of the white body using thermoformed steel are: A-pillar, B-pillar, C-pillar, upper side beam, door sill side beam, central channel, floor crossbeam, front fence panel, etc. The use of thermoformed parts for these key skeleton parts of the body can effectively ensure the integrity of the body frame structure in a collision, thus protecting passengers.

1. Production of drop sheets

The drop sheets are produced on the uncoiling line with a specific profile and then transported to the hot forming line where they are coded by a robot through a vacuum suction cup to a coding machine and then placed on a conveyor line for transfer to the heating furnace.

2. Metallographic austenitization

The initial metallographic organization of boron steel is ferrite and pearlite, we can see from the above figure that the Austenization stage of the hot forming process is first heated to 930-950℃ and then insulated to make the internal organization of the sheet completely austenitized.

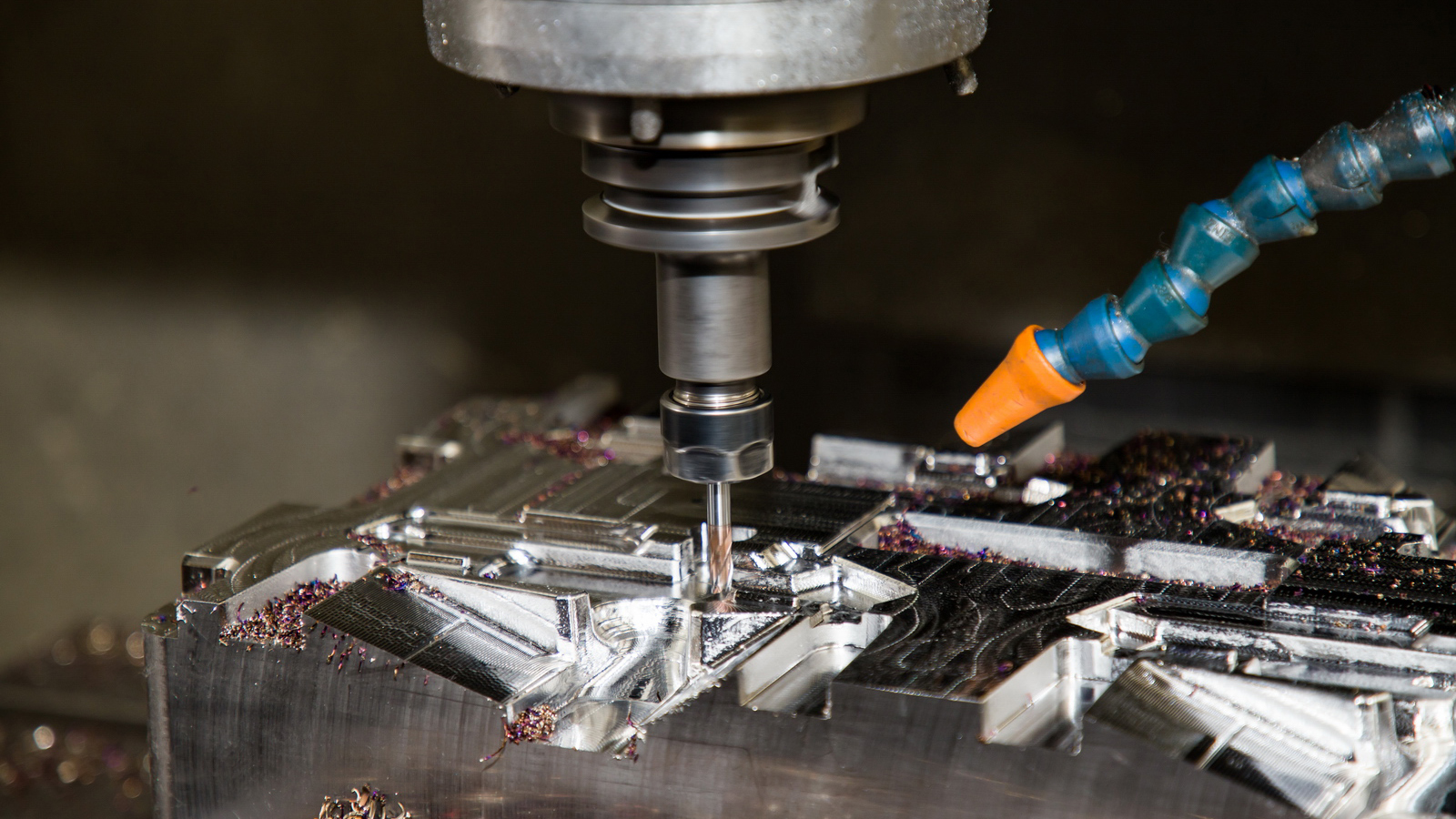

3. Hot stamping process

The key difference between hot stamping die and cold stamping die is the additional water cooling system, during the process of holding pressure and cooling (quenching), the metallographic organization of the sheet will be completely changed to martensite. The strength and hardness of martensite tissue is very high, the tensile strength of thermoformed parts can reach 1500MPa, and the surface hardness of parts can reach 52HRC.

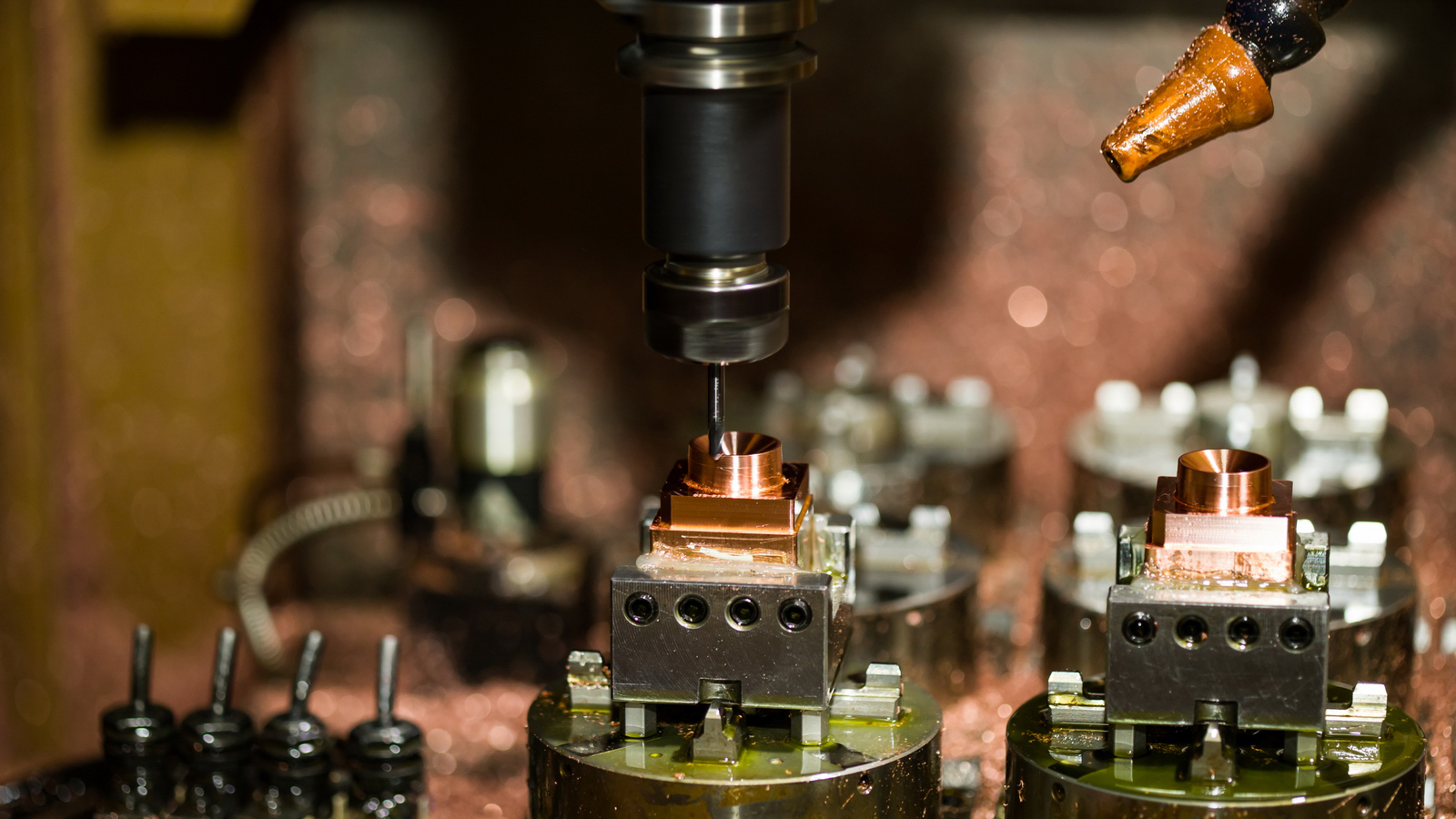

4. Laser cutting

Due to the high strength and hardness of thermoformed parts, the use of traditional cold stamping dies for trimming and punching results in severe wear and tear on the die parts and a severely shortened life span. The current solution is to equip 3-4 laser cutting robots at the end of the thermoforming line for trimming and punching.

5. Post-processing

Due to the oxidation of the surface of the parts at high temperatures during the thermoforming process, the parts are generally cleaned by shot blasting.