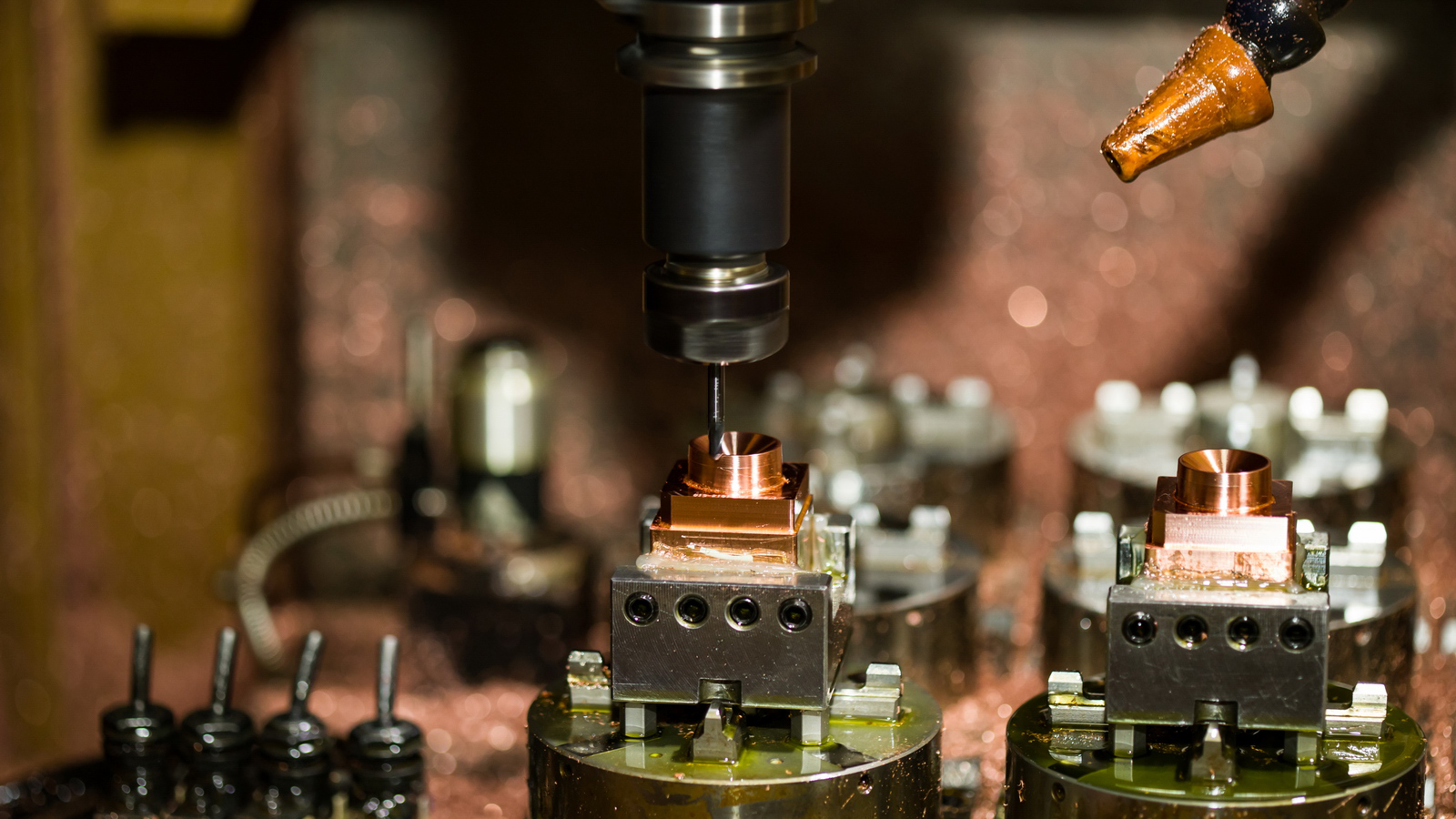

CNC machining

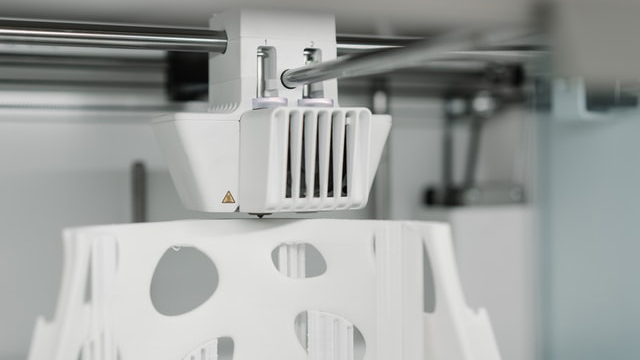

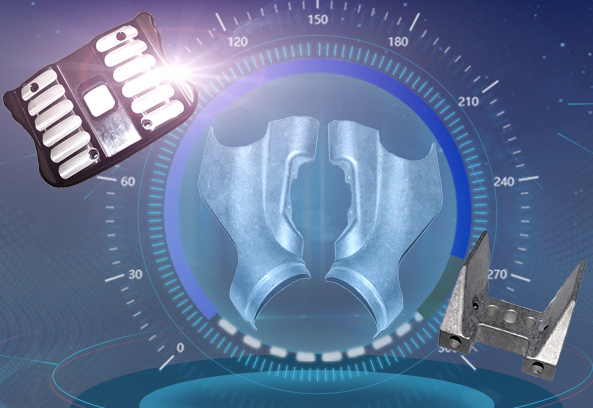

Mastars is a large plastic mold manufacturer specializing in the production and processing of plastic molds and plastic products. It is committed to providing professional injection molding and plastic mold manufacturing,custom metal stamping, rapid cnc services.

In recent years, in order to improve fuel efficiency, the requirements for lightweight of vehicles are becoming higher and higher. For this reason, the tensile strength of steel for cold stamping automobile parts exceeds 980mpa, causing the die temperature to rise. In hot stamping and die-casting processing, due to high temperature and rapid, the mold temperature also increases. In the aspect of plastic forming, due to the increase of the content of reinforcing fiber and hard particles in plastic, the working environment of forming die is getting worse and worse.

In this case, in order to meet the increasingly high requirements of molds, the use of surface treatment molds is essential.

When selecting the surface treatment method, it should be noted that it is necessary to know in advance how the characteristics of die steel materials (such as hardness, size and surface properties) will change under the treatment temperature. For example, when PVD (physical vapor deposition) is applied to the low-temperature tempered materials of cold working die steel, it should be noted that the tempering of die steel will reduce the hardness and change the size. When carrying out CVD (chemical vapor deposition) heat treatment and TRD (thermal reaction deposition diffusion) treatment on steel, due to the high treatment temperature, quenching and tempering shall be carried out after surface treatment. Therefore, the size change degree and deformation shall also be known in advance.

4. shot blasting

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China