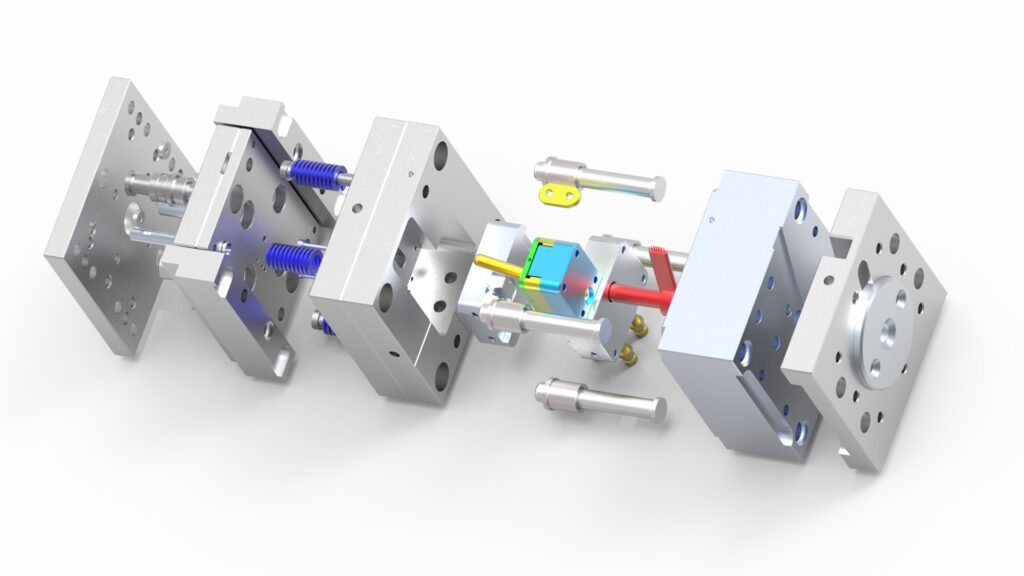

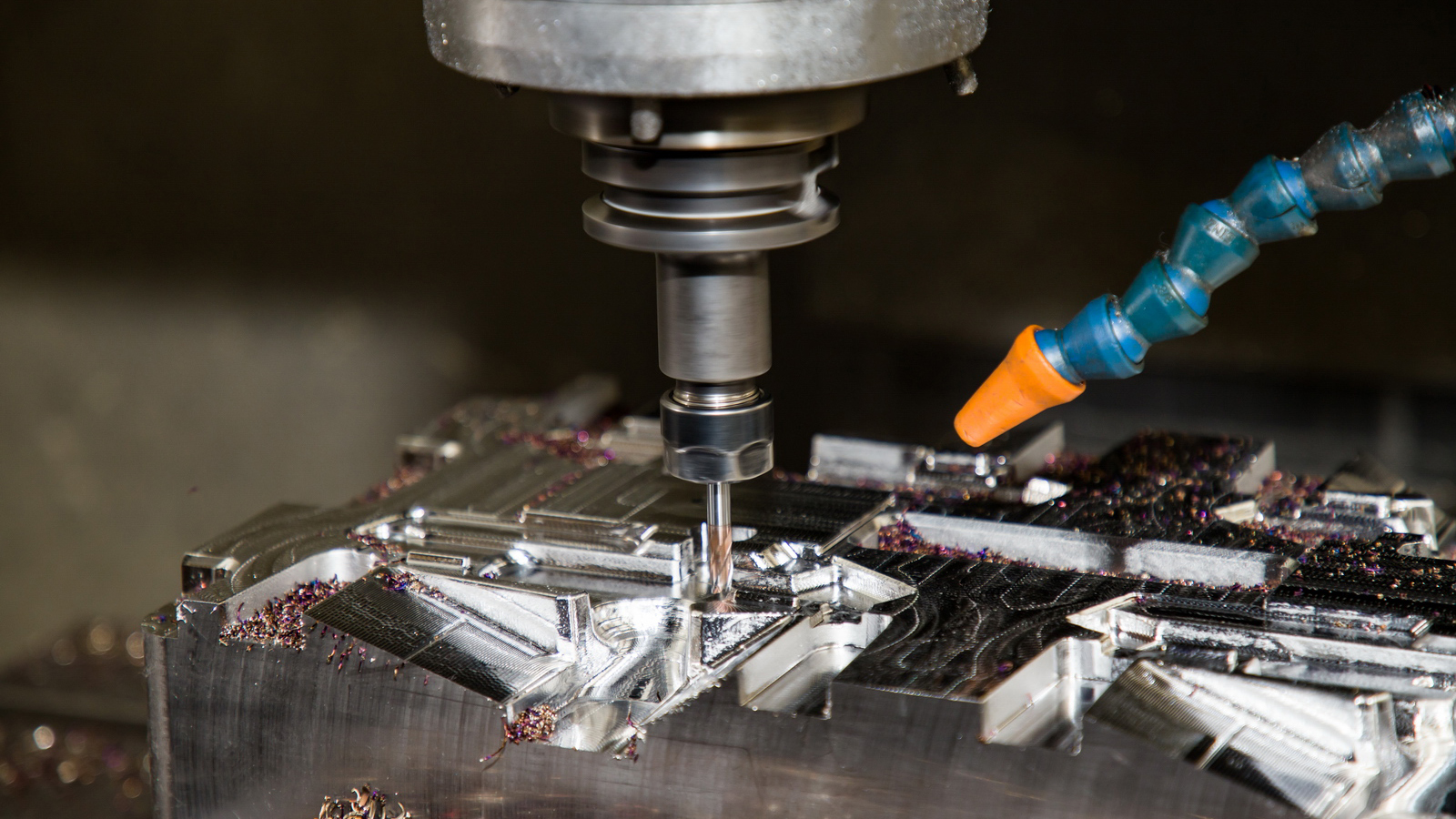

Mastars is dedicated to the extrusion, injection molding, and machining of various plastic products. We specialize in PEEK, PI, PPS, PEI, and provide special engineering plastic finished parts and semi-finished profiles for different industries.|rapid cnc machining|metal prototype maker

Plastic and metal thermal expansion coefficient difference of 5 to 10 times, and therefore with metal insert plastic products in the cooling, the formation of the two shrinkage degree is different, because the plastic shrinkage is relatively large and clinging to the metal insert, in the insert around the inner layer of plastic compressive stress, while the outer layer of tensile stress, resulting in stress concentration phenomenon.

In the specific set juice insert, the following points should be noted to help reduce or eliminate internal stress.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China