This vocabulary provides a solid foundation

for communicating effectively about the plastic extrusion process, from machine

operators and process engineers to product designers

Category 1: The Extrusion Line & Major

Components

|

Term |

Definition & Context |

|

Extrusion Line |

The complete set of equipment used in the

extrusion process, from raw material handling to the final product. |

|

Extruder |

The machine that melts and pumps the

plastic. It consists of a barrel, screw, and drive

motor. |

|

Hopper |

The container that holds and feeds the

plastic resin (usually in pellet form) into the extruder barrel. |

|

Barrel |

The heated, hardened steel cylinder that

houses the extruder screw. |

|

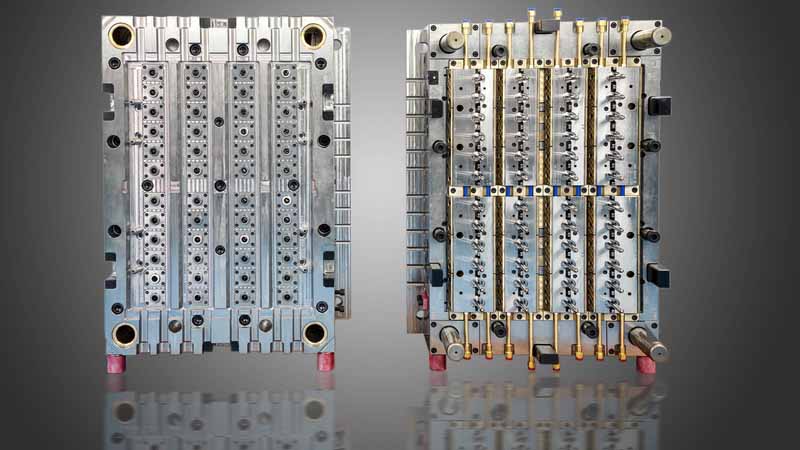

Die |

The precision-machined tool mounted at the

end of the extruder that shapes the molten plastic into the desired profile. |

|

Screen Pack / Filter Pack |

A stack of metal wire meshes placed between

the screw and the die to filter out contaminants and create backpressure. |

|

Breaker Plate |

A thick, perforated metal plate that

supports the screen pack. |

|

Downstream Equipment |

All equipment that handles the product

after it exits the die. This includes cooling, sizing, pulling, and cutting

units. |

|

Upstream Equipment |

Equipment that handles material before the

extruder, such as dryers, blenders, and feeders. |

Category 2: The Screw & The Plasticating Process

|

Term |

Definition & Context |

|

Screw |

The rotating shaft inside the barrel that

conveys, melts, and pumps the plastic. Its design is critical to the process. |

|

Flight |

The helical ridge on the screw. |

|

Root |

The central shaft of the screw. The root

diameter often changes along the screw's length. |

|

Channel |

The space between the flights. |

|

Channel Depth |

The distance from the root to the top of

the flight. Changes in depth define the screw zones. |

|

Feed Zone (Solid Conveying Zone) |

The first section of the screw. Its deep

flights convey solid pellets forward from the hopper. |

|

Compression Zone (Transition Zone) |

The middle section where the channel depth

decreases. This compresses the material, which, combined with heat, melts the

plastic. |

|

Metering Zone (Melt Pumping Zone) |

The final section with a shallow, constant

channel depth. It generates pressure to pump the homogenized melt through the

die at a consistent rate. |

|

Length-to-Diameter Ratio (L/D Ratio) |

The ratio of the screw's flighted length to

its diameter (e.g., 24:1). A higher L/D ratio allows for better melting and

mixing. |

|

Compression Ratio |

The ratio of the channel volume in the feed

zone to the channel volume in the metering zone. It indicates the screw's

melting capability. |

|

Mixing Section |

A specialized section on the screw (e.g., Maddock

mixer, pineapple

mixer) designed to homogenize the melt temperature and composition. |

|

Vented Barrel (Two-Stage Screw) |

A barrel with a vent port to remove

moisture or volatiles. Requires a special two-stage screw with a decompression

zone under the vent. |

Category 3: Dies & Tooling

|

Term |

Definition & Context |

|

Die |

The tool that shapes the extrudate. |

|

Die Body / Die Holder |

The main block of the die assembly. |

|

Mandrel (Spider Mandrel, Torpedo) |

A central pin used in dies for hollow

profiles (like pipes) to form the inner surface. |

|

Die Land |

The final, parallel section of the die

channel where the melt is stabilized before exiting. The length of the die

land is critical for controlling surface finish and dimensions. |

|

Adapter (Crosshead) |

A section that connects the extruder barrel

to the die, often used to change the flow direction (e.g., in wire coating). |

|

Die Swell (Extrudate Swell) |

The phenomenon where the extrudate expands

as it exits the die due to the relaxation of polymer molecules. Die design

must compensate for this. |

|

Spider Legs |

The arms that hold a mandrel in place

inside a die. They leave witness lines (spider lines) on the

extrudate where the plastic flows around them. |

|

Coathanger Die / Manifold |

The internal channel design in a flat sheet

or film die that distributes the melt evenly across the width of the die. |

Category 4: Process Parameters & Control

|

Term |

Definition & Context |

|

Throughput (Output Rate) |

The mass of material extruded per unit of time

(e.g., kg/hour, lbs/hour). |

|

Screw Speed (RPM) |

The rotational speed of the extruder screw.

A primary control for throughput. |

|

Melt Temperature (T melt) |

The actual temperature of the molten

plastic as it exits the die. |

|

Melt Pressure |

The pressure of the molten plastic,

typically measured just before the screen pack or die. High pressure can

indicate a blockage. |

|

Barrel Temperature Zones |

The barrel is divided into multiple

heating/cooling zones (e.g., rear, middle, front, adapter) to precisely

control the melting profile. |

|

Backpressure |

The resistance to flow. Created by the

screen pack, breaker plate, and die. Essential for proper melting and mixing. |

|

Residence Time |

The amount of time the plastic spends

inside the extruder. |

|

Parison |

The tubular extrudate used in extrusion

blow molding to make bottles. |

Category 5: Downstream Equipment & Processes

|

Term |

Definition & Context |

|

Sizing (Calibration) |

The process of setting the final dimensions

of the still-molten extrudate. Often done with a vacuum sizer or sizing

sleeve that uses vacuum and cooling water. |

|

Cooling Tank / Water Bath |

A long tank filled with water that cools

the extruded product. |

|

Haul-Off (Puller) |

A device (often with caterpillar tracks)

that grips the cooled product and pulls it at a constant speed, stabilizing

the line. |

|

Cutter (Saw, Guillotine Cutter) |

Cuts the continuous extrudate to the

desired length. |

|

Winder / Coiler |

A machine that winds flexible extrudates

(like film, sheet, or tubing) onto rolls. |

|

On-The-Fly Perforation / Punching |

Downstream units that add holes or cutouts

to the profile while it is moving. |

Category 6: Products & Specific Processes

|

Term |

Definition & Context |

|

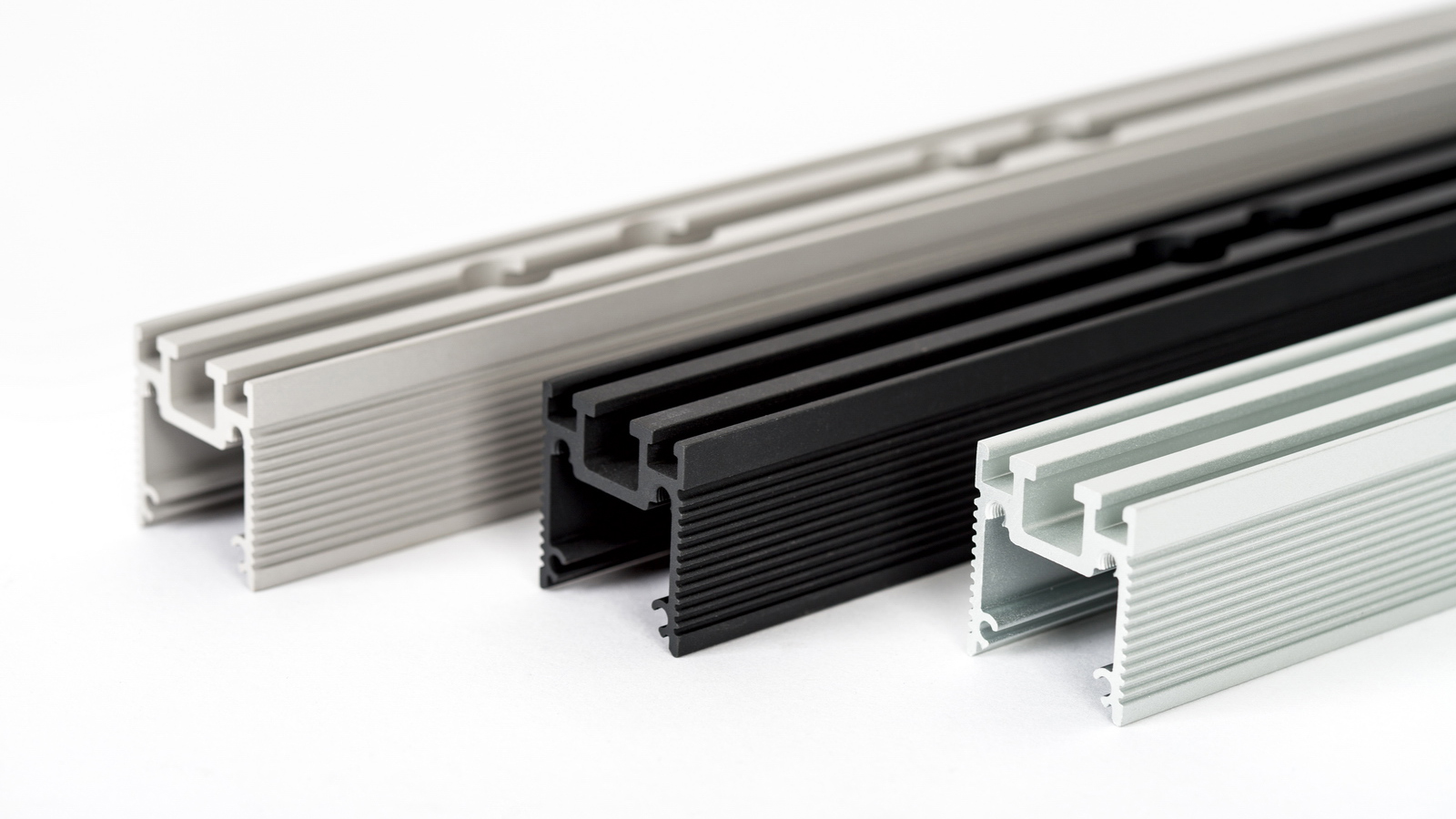

Profile Extrusion |

The extrusion of any continuous shape with

a constant cross-section (e.g., window frames, deck railings). |

|

Tube/Pipe Extrusion |

Extrusion of hollow, cylindrical profiles. |

|

Sheet Extrusion |

Production of wide, flat sheets using a

flat die and a set of cooling rolls (calendar stack). |

|

Blown Film Extrusion |

A process where a tube of plastic is

extruded upward and inflated like a balloon, then collapsed to form a double

layer of film. |

|

Cast Film Extrusion |

A process where the melt is extruded

through a flat die directly onto a chilled roll to produce film. |

|

Coextrusion |

The process of extruding two or more

different materials simultaneously through a single die to create a

multi-layer product. |

|

Extrusion Coating |

The process of extruding a thin film of

molten plastic onto a substrate like paper, foil, or fabric. |

Category 7: Defects & Quality

|

Term |

Definition & Context |

|

Surging |

An unstable, cyclical variation in output,

leading to inconsistent dimensions. Often caused by poor screw design or

feeding problems. |

|

Die Lines |

Visible lines running in the machine

direction on the extrudate, caused by a scratch in the die or contamination. |

|

Melt Fracture |

A surface defect where the extrudate

appears rough or wavy, caused by excessive shear stress at the die entrance. |

|

Degradation |

The breakdown of the polymer due to

excessive heat or shear, leading to discoloration, black specs, and loss of

properties. |

|

Shark Skin |

A surface defect characterized by a matte,

rough finish, often occurring at high output rates. |