Category 1: Fundamental Processes &

Operations

|

Term |

Definition & Context |

|

Blanking |

A cutting operation where the punched-out

piece (the

blank) is the desired part. The surrounding material is scrap. |

|

Piercing |

A cutting operation where a hole is punched

into the workpiece. The punched-out piece is scrap (slug), and the

remaining strip is the part. |

|

Punching |

Often used interchangeably with piercing,

but can refer to the general act of creating a hole. |

|

Bending |

The process of deforming metal around a

straight axis to create an angle. |

|

Forming |

A general term for any operation that

changes the shape of the metal without cutting or shearing, including

bending, drawing, and flanging. |

|

Drawing |

A forming operation where a punch forces a

blank into a die cavity to create a deep, three-dimensional shape (e.g., a

cup). The metal thickness changes as it flows. |

|

Stretching |

A forming operation where the surface area

of the metal increases, thinning the material as it is stretched over a form. |

|

Coining |

A high-precision compression operation that

squeezes metal within a closed die to imprint fine details or achieve

critical dimensions. Minimal material flow occurs. |

|

Embossing |

A process that creates raised or recessed

designs, lettering, or ribs in the material to add stiffness or for

decorative purposes. |

|

Notching |

Cutting a portion of material from the edge

of a workpiece. |

|

Lancing |

Making a partial cut and bending the

material to create a feature like a vent, louver, or tab without separating

any material from the strip. |

|

Trimming |

Cutting away excess or irregular flash from

a drawn or formed part to finalize its profile. |

|

Shaving |

A secondary cutting operation that removes

a small amount of material from a previously cut edge to achieve a smoother

finish and tighter tolerance. |

Category 2: Tooling (Dies & Molds)

|

Term |

Definition & Context |

|

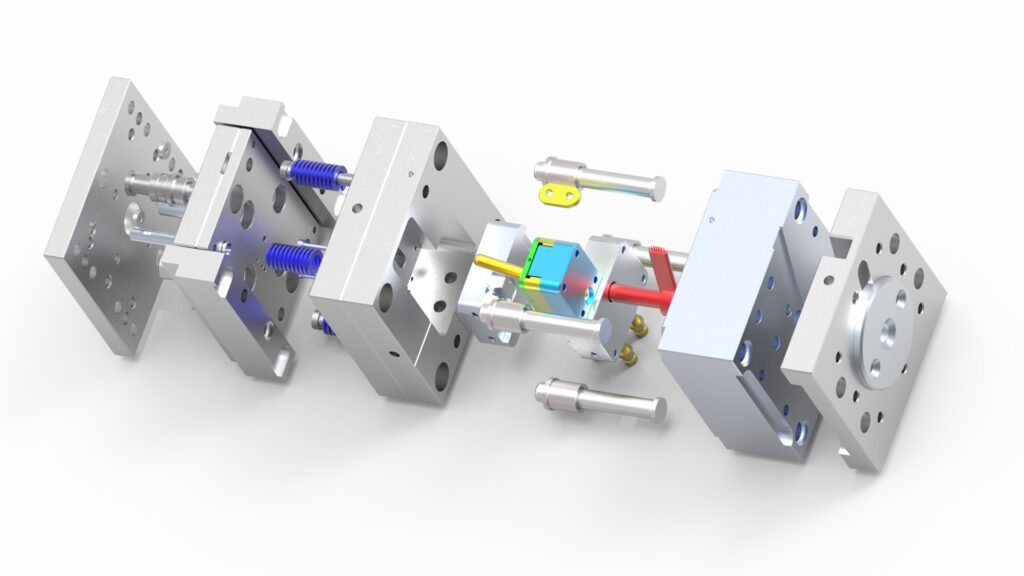

Die |

The entire tooling assembly used in a press

to cut or form metal. It consists of a Punch (upper, male

part) and a Die (lower, female

part). |

|

Punch |

The hardened tool steel component that is

mounted on the press ram and moves into the stationary die to perform the

operation. |

|

Die Set |

A standardized assembly that includes guide

pins (or pillars) and bushings to ensure

precise alignment between the upper and lower halves of the tool. |

|

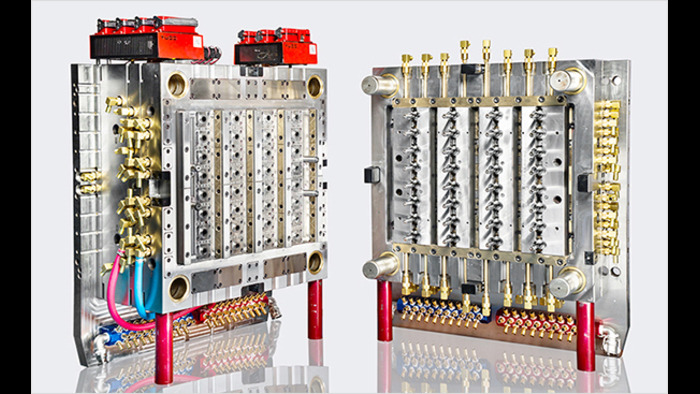

Progressive Die |

A die with multiple stations. A metal strip

feeds through it, and a different operation is performed at each station with

each press stroke. A finished part is cut off at the final station. |

|

Compound Die |

A die that performs multiple operations

(e.g., blanking and piercing) in a single station with one stroke of the

press. |

|

Transfer Die |

A system where an individual blank is

mechanically moved (transferred) from one

station to the next within a single press for secondary operations. |

|

Pilot |

A precision pin in the die that enters a

previously pierced hole to accurately position the strip for the next

operation in a progressive die. |

|

Stripper Plate |

A plate that holds the material strip down,

preventing it from sticking to the punch as it retracts. |

|

Knockout |

A mechanism inside the die that pushes the

finished part or slug out of the die cavity. |

|

Nitrogen Cylinder / Gas Spring |

A component used within the die to provide

a strong, consistent force for actions like lifting the stripper plate or

actuating pads. |

Category 3: Materials & Blanks

|

Term |

Definition & Context |

|

Coil |

A continuous roll of sheet metal that is

fed into a progressive die press. |

|

Blank |

A flat piece of sheet metal, either cut

from a coil or sheet, that is ready for forming. |

|

Strip |

The continuous piece of metal, often from a

coil, that is fed through a progressive die. |

|

Temper |

The hardness and strength of the metal

(e.g., H32, O-temper). |

|

Grain Direction |

The directional alignment of the metal's

crystalline structure resulting from the rolling process. It affects

formability, especially in bending. |

Category 4: Part & Process Features

|

Term |

Definition & Context |

|

Burr |

A sharp, rough edge of material that

remains on the workpiece after a cutting or shearing operation. |

|

Deburring |

The process of removing burrs to create a

safe, smooth edge. |

|

Slug |

The small piece of scrap material punched

out to create a hole. |

|

Web |

The thin, flat section of material that

connects features in a strip layout; often the area where the part is

attached to the carrier strip before being cut free. |

|

Carrier Strip |

The portion of the strip that conveys the

partially formed parts through the progressive die. |

|

Parting Line |

The line on a stamped part that corresponds

to where the punch and die meet. |

|

Bend Radius |

The inside radius of a bend. |

|

Bend Allowance (BA) |

The length of the neutral axis (the part

that doesn't stretch or compress) between the bend lines. Used to calculate

the flat pattern length. |

|

Bend Deduction (BD) |

The amount of material to be subtracted

from the sum of the two flanges to get the correct flat pattern length. |

|

K-Factor |

A ratio used to calculate the bend

allowance. It represents the location of the neutral axis in the material

thickness. |

|

Springback |

The elastic recovery of the metal after

bending, causing the final bend angle to be slightly more open than the angle

in the die. The die must be designed to overbend to compensate. |

|

Neutral Axis |

The plane within the material that

experiences neither compression nor tension during bending. |

Category 5: Defects & Quality

|

Term |

Definition & Context |

|

Warpage/Twisting |

Distortion of the part after stamping,

often caused by residual stresses or uneven material flow. |

|

Wrinkling |

A defect occurring in drawing or stretching

where the metal buckles or forms wrinkles due to excessive compressive

stresses. |

|

Tearing / Splitting |

A crack or rupture in the material caused

by being stretched beyond its formability limits. |

|

Die Mar / Scratch |

A surface scratch on the part caused by

contact with the tooling. |

|

Gallling |

A condition where the workpiece material

adheres (welds) to the tooling surface due to friction and pressure. |

This vocabulary provides a comprehensive

foundation for communicating effectively with tool and die engineers, stamping

press operators, and quality control personnel in the metal stamping industry.