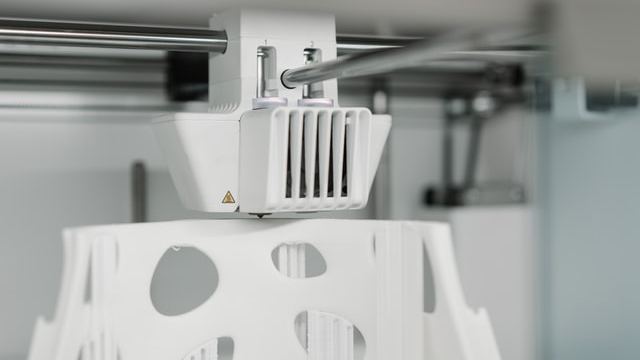

Material forming method is an important part of part design, and also a key factor in the processing process. In addition to machining, metal injection molding, plastic molding and 3D printing, which have sprung up in recent years, are the main technologies. Let's take a closer look at the characteristics of these metal forming processes.|custom metal stamping

Process flow: liquid metal → mold filling → solidification shrinkage → casting

It refers to the method that liquid metal fills the mold under the action of low pressure (0.02 ~ 0.06mpa) and crystallizes under pressure to form castings.

4. The feeding riser is omitted, and the metal utilization rate is increased to 90 ~ 98%;

A casting method in which molten metal is poured into a rotating mold, and the mold is filled and solidified under the action of centrifugal force.

Centrifugal casting was first used to produce cast pipes. Centrifugal casting technology is used in metallurgy, mining, transportation, drainage and irrigation machinery, aviation, national defense, automobile and other industries at home and abroad to produce steel, iron and non-ferrous carbon alloy castings. Among them, the production of castings such as centrifugal cast iron pipes, cylinder liners and shaft sleeves of internal combustion engines is the most common.

According to the forming mechanism, forging can be divided into free forging, die forging, rolling ring and special forging.

Special forging: including roll forging, cross wedge rolling, radial forging, liquid die forging and other forging methods, which are more suitable for the production of some special shaped parts.

4. Free forging is suitable for single piece and small batch production with great flexibility.

Rolls and herringbone gears of large rolling mills, rotors, impellers and retaining rings of steam turbine generator sets, huge hydraulic press cylinders and columns, locomotive shafts, crankshafts and connecting rods of automobiles and tractors, etc.