Manufacturing: Professional Terminology

Category 1: Core Concepts & Philosophies

|

Term |

Definition & Context |

|

Manufacturing |

The process of transforming raw materials

into finished goods on a large scale. |

|

Production |

Often used interchangeably with

manufacturing, but can have a broader meaning that includes creation of

non-tangible goods (e.g., software production). |

|

Value-Added |

The process of increasing the economic

value of a material by changing its form or function. The core goal of

manufacturing. |

|

Discrete Manufacturing |

The production of distinct, countable items

(e.g., automobiles, smartphones, screws). |

|

Process Manufacturing |

Production that uses formulas or recipes,

resulting in products that cannot be disassembled (e.g., chemicals,

pharmaceuticals, gasoline). |

|

Assembly |

The process of putting together components

to create a final product. |

|

Fabrication |

Often refers to the process of making

individual components, particularly from metal or wood (e.g., sheet metal

fabrication). |

Category 2: Production Systems & Methodologies

|

Term |

Definition & Context |

|

Mass Production |

The high-volume manufacturing of

standardized goods, often using assembly lines. |

|

Batch Production |

Manufacturing a specific quantity (a

"batch") of a product. Equipment is reconfigured between batches. |

|

Job Shop Manufacturing |

A facility that handles custom, low-volume

production runs. Characterized by high flexibility and general-purpose

equipment. |

|

Lean Manufacturing |

A systematic method for waste minimization

(Muda) without

sacrificing productivity. |

|

Just-In-Time (JIT) |

An inventory strategy where components

arrive exactly when they are needed in the production process. |

|

Toyota Production System (TPS) |

The pioneering system that inspired Lean

Manufacturing, focusing on eliminating waste and continuous improvement. |

|

Automation |

The use of control systems (e.g., PLCs,

robots) to operate equipment with minimal human intervention. |

|

Computer-Integrated Manufacturing (CIM) |

The use of computers to control the entire

production process. |

|

Industry 4.0 |

The current trend of automation and data

exchange in manufacturing, including Cyber-Physical Systems (CPS), the Internet

of Things (IoT), and the Smart Factory. |

|

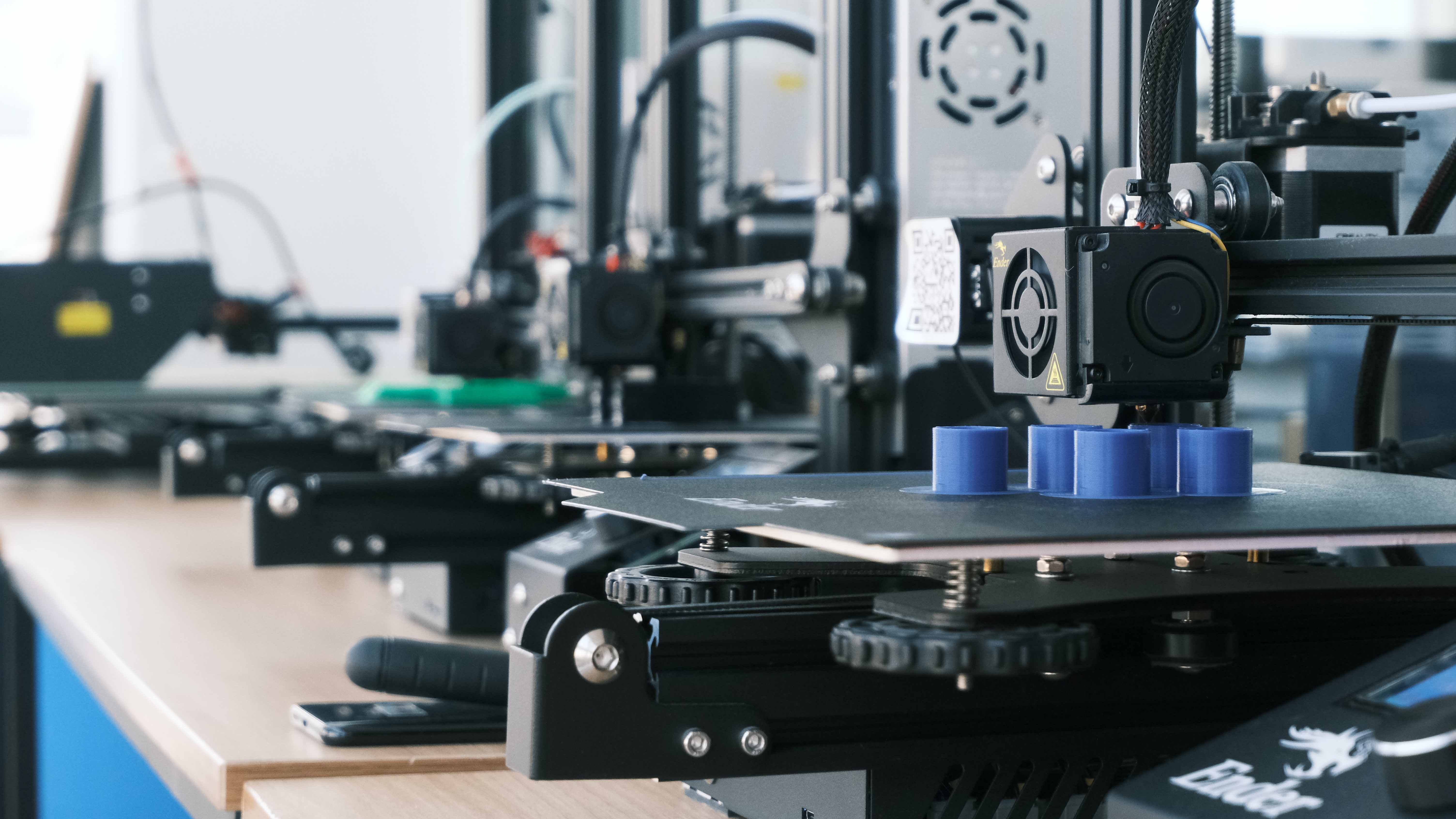

Additive Manufacturing (AM) |

The formal term for 3D printing; building

parts layer-by-layer from a digital model. |

|

Subtractive Manufacturing |

Processes that create a part by removing

material from a solid block (e.g., CNC Machining). |

|

Formative Manufacturing |

Processes that shape material by deforming

it (e.g., Casting, Forging). |

Category 3: Design & Engineering

|

Term |

Definition & Context |

|

Computer-Aided Design (CAD) |

Software used to create 2D and 3D models of

a product. |

|

Computer-Aided Manufacturing (CAM) |

Software that uses CAD models to generate

toolpaths for CNC machines. |

|

Computer-Aided Engineering (CAE) |

The use of software for simulation,

validation, and optimization of products and manufacturing tools (e.g., FEA,

CFD). |

|

Geometric Dimensioning & Tolerancing

(GD&T) |

A symbolic language used on engineering

drawings to define the allowable variation in form, orientation, and location

of part features. |

|

Bill of Materials (BOM) |

A comprehensive list of raw materials,

components, and instructions required to manufacture a product. |

|

Design for Manufacturability (DFM) |

The practice of designing products to make

them easier and cheaper to manufacture. |

|

Design for Assembly (DFA) |

The practice of designing products with a

minimal number of parts to make assembly easier and faster. |

|

Rapid Prototyping |

Technologies used to quickly produce a

physical part or model for concept validation and testing. |

Category 4: Processes & Operations

|

Term |

Definition & Context |

|

Casting |

Pouring liquid material into a mold where

it solidifies (e.g., Die Casting, Investment Casting). |

|

Molding |

Shaping material using a rigid frame or

pattern (e.g., Injection Molding, Blow Molding). |

|

Forming |

Deforming material without adding or

removing it (e.g., Forging, Stamping, Rolling). |

|

Machining |

A subtractive process using machine tools

(e.g., Milling, Turning, Drilling, Grinding). |

|

Joining |

Processes to connect materials (e.g., Welding, Brazing, Soldering, Adhesive

Bonding). |

|

Finishing |

Processes applied to the surface of a

product (e.g., Painting, Plating, Powder

Coating, Anodizing). |

|

Heat Treatment |

Controlled heating and cooling of metals to

alter their physical properties (e.g., hardness, strength). |

Category 5: Quality & Metrology

|

Term |

Definition & Context |

|

Quality Control (QC) |

The process of ensuring products meet

specified requirements through inspection and testing. |

|

Quality Assurance (QA) |

The process of preventing defects by

focusing on the manufacturing process itself. |

|

Statistical Process Control (SPC) |

Using statistical methods to monitor and

control a process to ensure it operates at its full potential. |

|

Tolerance |

The permissible limit of variation in a

physical dimension. |

|

Metrology |

The science of measurement. |

|

Calibration |

Comparing a measurement device against a

standard to ensure its accuracy. |

|

First Article Inspection (FAI) |

A comprehensive verification of a part

before full production begins to ensure it meets all design specifications. |

|

Non-Conformance / Non-Conformity |

A failure of a characteristic to meet

specified requirements. |

|

Corrective and Preventive Action (CAPA) |

A process to investigate and address the

root cause of non-conformities. |

Category 6: Facility & Operations Management

|

Term |

Definition & Context |

|

Supply Chain |

The entire network from raw material

sourcing to delivery of the final product to the end consumer. |

|

Logistics |

The management of the flow of goods between

the point of origin and the point of consumption. |

|

Inventory |

Raw materials, work-in-progress (WIP), and

finished goods held by a company. |

|

Work-in-Progress (WIP) |

Partially finished goods awaiting

completion. |

|

Throughput |

The rate at which a system produces

finished goods. |

|

Cycle Time |

The total time to complete one operation or

produce one unit. |

|

Lead Time |

The total time from when a customer places

an order to when the final product is delivered. |

|

Overall Equipment Effectiveness (OEE) |

A metric that measures the utilization of a

manufacturing asset by evaluating availability, performance, and quality. |

|

Preventive Maintenance (PM) |

Regularly scheduled maintenance to prevent

equipment failure. |

|

Gemba |

A Japanese term meaning "the real

place." In manufacturing, it refers to the shop floor where value is

added. Going to the Gemba means observing the process firsthand. |

This vocabulary provides a solid foundation

for communicating effectively across engineering, production, and management

functions within the manufacturing industry.