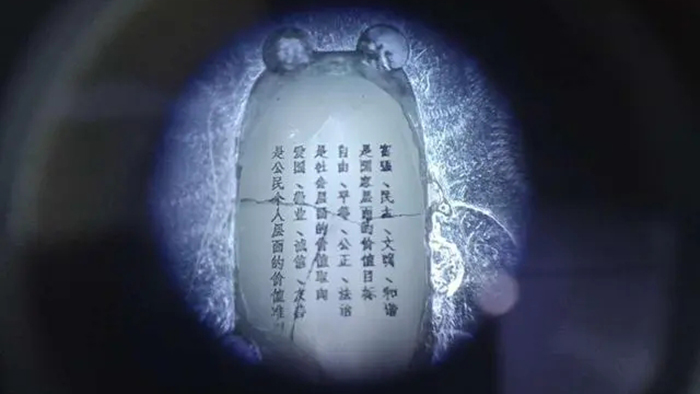

Lenovo team is determined to continue to explore the possibility of using high percentage recycled materials in ThinkPad batteries, and boldly challenge higher challenges! After dozens of formula adjustments, more than a hundred tests and verifications, and adjustments to the molding process, it achieved extremely high requirements while solving the problems of short shot, trapped air, and unsatisfied filling, successfully opening a new era of 97% recycling ratio for batteries.

In April 2022, Lenovo successfully mass-produced the industry's first 97% PCC battery in ThinkPad, further driving the process of accelerating the application of high-recycling ratio plastics in the notebook industry. Compared to the 25%-30% PCC batteries commonly used in the industry, this environmentally friendly and cutting-edge PCC 97% battery makes a significant contribution to Lenovo's ESG strategy - it can reduce 80 tons of virgin plastic use and 171 tons of CO2 emissions in one year when used in 10 ThinkPad products.

It is understood that Lenovo will continue to promote the wider use of high percentage PCR materials in keycaps, high-power power adapters and cases for ThinkPad products in the coming years.

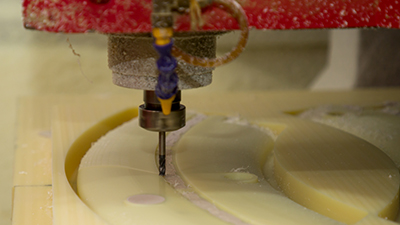

If your rapid prototypings or functional parts need injection molding, please contact Mastars, we will develop the best solution for you, provide you with products that exceed your expectations and one-stop service.