Injection Tooling: A Detailed Overview

1. Executive Summary

Injection Tooling refers to the high-precision,

custom-built tool—most commonly called a mold (in the US) or tool (in Europe)—used in the injection molding

process. It is the engineered system that gives molten plastic its shape,

cooling it into a solid, functional part. The mold is the single most critical

and expensive element in the injection molding workflow, representing a

significant capital investment. Its design and construction directly determine

the part's quality, dimensional accuracy, production efficiency, and ultimate

cost.

2. Core Components of an Injection Mold

A standard

injection mold is a complex assembly of several key components, typically

categorized into the "A Side" and "B Side."

A-Side (Cavity Side / Fixed

Half):

B-Side (Core Side / Moving

Half):

Major Mold Components:

|

Component |

Description & Function |

|

Core & Cavity |

The master forms that create the part's

geometry. The cavity forms the

part's outer surface; the core forms the inner surface. |

|

Mold Base |

A standardized frame that holds all the

custom-machined components. It is typically purchased as a pre-made unit,

saving cost and time. It includes plates like the "A"

and "B" plates. |

|

Sprue Bushing |

A hardened steel nozzle that connects the

mold to the injection molding machine's nozzle, channeling molten plastic

into the mold. |

|

Runner System |

The network of channels that carries molten

plastic from the sprue to the part cavities. |

|

Gates |

The small, controlled entrance points from

the runner into the part cavity. Gate design is critical for controlling

plastic flow and part quality. |

|

Ejection System |

The mechanism that pushes the cooled part

off the core after the mold opens. It includes: |

|

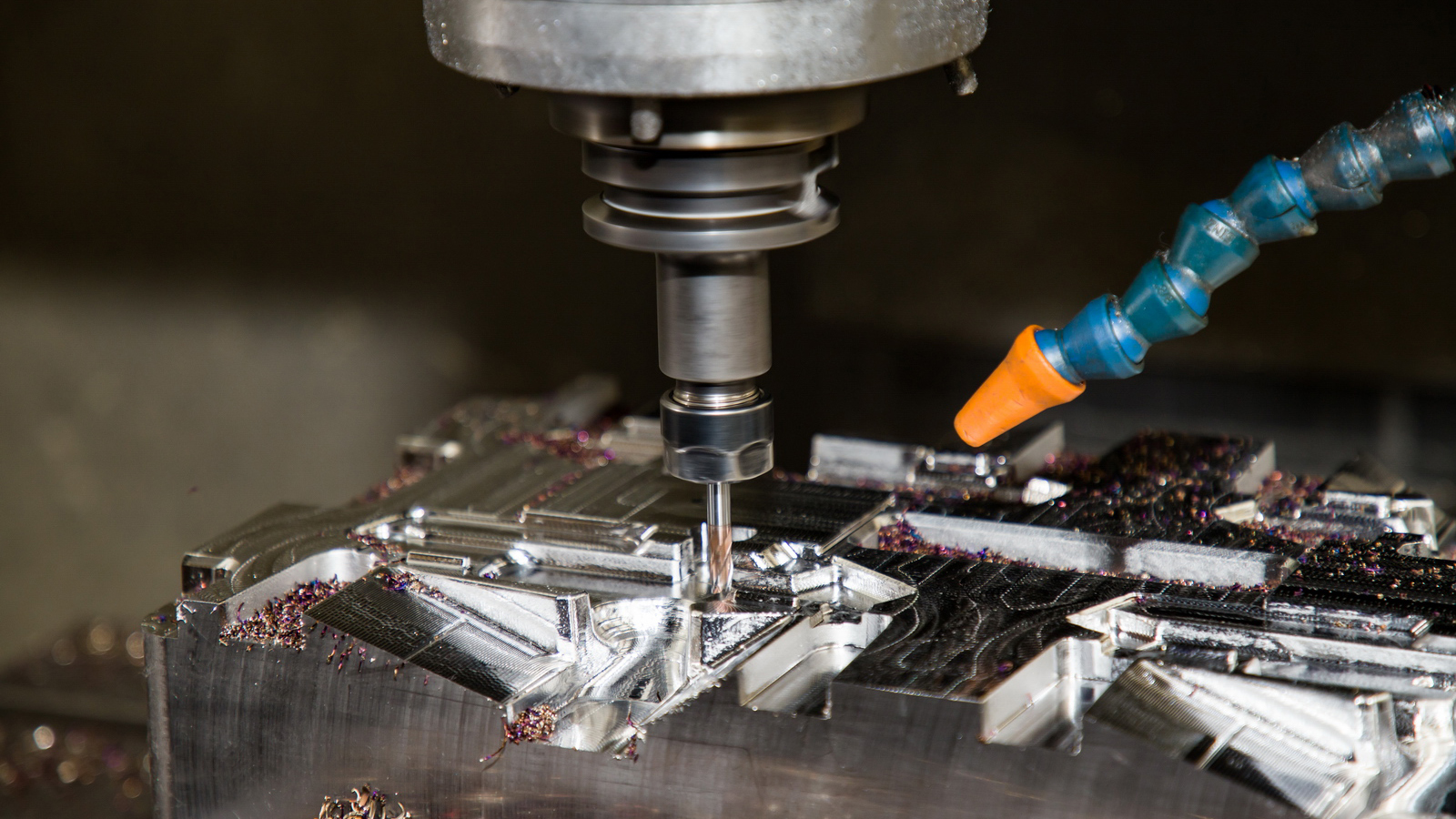

Cooling (Temperature Control) System |

A series of channels drilled through the

mold plates and core/cavity blocks. Circulating water or oil through these

channels controls the mold temperature, which is vital for cycle time and

part quality. |

|

Venting |

Very shallow channels (often only 0.01-0.03

mm deep) cut into the mold to allow trapped air to escape during injection,

preventing defects like burns or short shots. |

|

Guide Pins/Bushings |

Precision components that ensure the two

halves of the mold align perfectly each time they close. |

3. Types of Injection Molds

Molds are

classified based on their construction and the type of runner system they use.

A. By Runner System:

|

Type |

Description |

Pros & Cons |

|

Two-Plate Mold |

The simplest and most common type. The

runner system and parts are on the same parting line and are ejected

together. |

Pros: Simple design,

lower cost. |

|

Three-Plate Mold |

Features two parting lines. One opens to

eject the runner system, and a second opens to eject the part. This allows

the gate to be located away from the part's edge. |

Pros: Automatic

degating (runners separate from parts), gates can be placed at optimal

locations. |

|

Hot Runner Mold |

The runner system is heated and remains in

a separate, heated manifold plate, so the plastic within it stays molten. No

runner is ejected. |

Pros: No scrap

runners, faster cycle times, fully automated. |

B. By Production Volume &

Material:

|

Type |

Typical Material |

Mold Life |

Application |

|

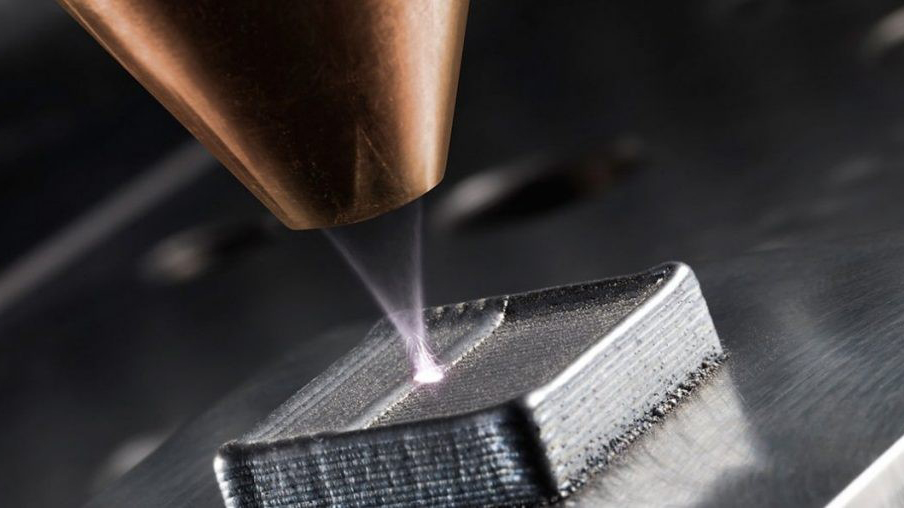

Prototype / Soft Tooling |

Aluminum, mild steel, 3D

printed metal/epoxy. |

1 - 10,000 shots |

Low-volume production, prototyping, and

market testing. Faster and cheaper to build. |

|

Production / Hard Tooling |

Hardened Steel (e.g., P20,

H13, S7). |

1,000,000+ shots |

High-volume mass production. Highly

wear-resistant but takes longer and costs more to build. |

4. Key Terminology in Mold Design & Manufacturing

|

Term |

Definition & Context |

|

Parting Line (PL) |

The visible line on the part where the two

mold halves meet. Its location is a critical design decision. |

|

Draft Angle |

A slight taper (typically 1°-3°) applied to

walls parallel to the mold opening direction. Essential for easy part

ejection. |

|

Shrinkage |

The reduction in volume of the plastic as

it cools. The mold must be built larger than the final

part dimension to compensate for the specific plastic's shrinkage rate. |

|

Undercut |

A feature on the part that prevents its

direct ejection from the mold (e.g., a side hole, a hook). Requires special

mold features. |

|

Lifter |

A component that moves at an angle to

release an undercut as the mold opens or during ejection. |

|

Slide (or Cam) |

A component that moves perpendicular to the

mold opening direction to form undercuts on the side of a part. |

|

Texture (EDM, Etching) |

The process of applying a surface finish

(e.g., leather grain, matte finish) to the mold cavity, often via Electrical

Discharge Machining (EDM) or chemical etching. |

|

Mold Flow Analysis |

Computer simulation software used during

the design phase to predict how the plastic will fill the mold, allowing

engineers to optimize gate location, cooling, and prevent defects. |

5. The Mold Lifecycle

Conclusion

Injection tooling is a sophisticated field of

engineering that blends precision machining, material science, and an intimate

understanding of polymer behavior. The quality of the tool directly dictates

the success of the entire production effort, making its design and construction

a critical phase in bringing a plastic product to market