Mastars manufactures high quality and precision products for the automotive, electronics, medical and outdoor industries.we provides rapid CNC services, rapid prototyping services, and custom metal stamping

Child safety seat skeleton manufacturing process is divided into injection molding process, blow molding process, and the combination of the two processes three.

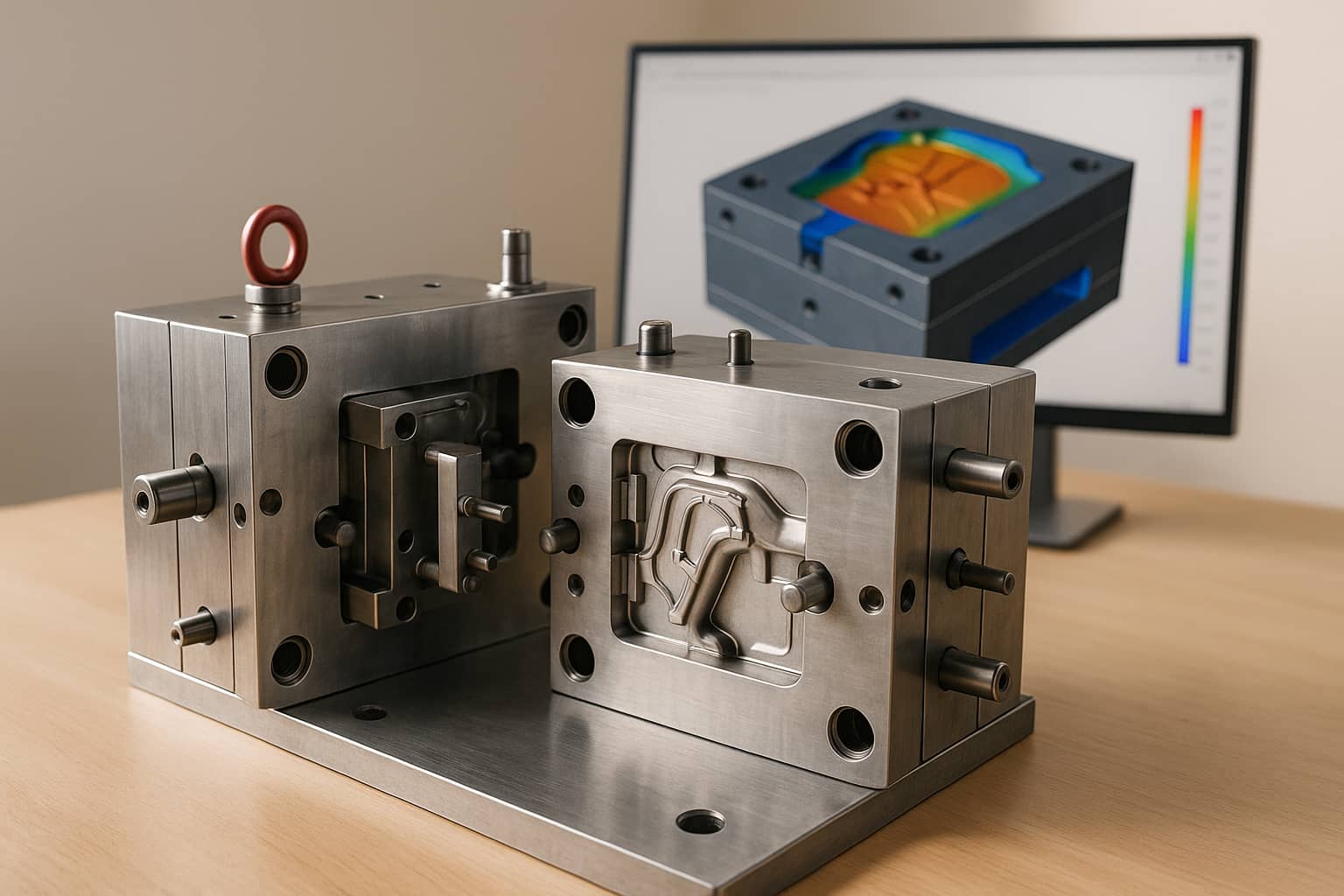

Injection molding process:

Injection molding is to use the injection machine screw or plunger to make the barrel of molten material, through the injection machine nozzle, mold pouring system, injected into the shape cavity and curing molding.

Advantages: High dimensional accuracy, smooth surface of complex structures.

Disadvantages: high cost of the mold to ensure the strength of the structure, the need to increase the filler.

Material: PP, polypropylene, density of 0.90-0.91g/cm3, has the advantages of small specific gravity, good rigidity, high strength, flexural resistance, as well as a heat-resistant temperature above 100 ℃ and good chemical resistance. The disadvantage is that the low temperature impact resistance is poor, easy to aging, molding shrinkage rate is large.

Blow molding process:

Blow molding is the extrusion of molten plastic blanks, placed in the mold, with the help of compressed air blowing expansion and paste on the cavity wall, after cooling and hardening for plastic parts.

Advantages: the overall structure of the product is more rigid, low mold cost.

Disadvantages: poor surface quality; can't mold complex structure products; uneven wall thickness and unstable size.

Material used: HDPE, high-density polyethylene, natural color columnar or flat round particles, with good tensile strength, bending strength, compression strength, shear strength and other mechanical properties, and improve the barrier properties of water vapor and gas.

Injection molding process and blow molding process have their own advantages and disadvantages, child safety seats to choose a certain process, in addition to the cost involved, but also need to be based on various factors such as the shape of the product