In the competitive world of manufacturing, rapid and reliable sheet metal prototyping is crucial for product development. Mastars stands as your trusted partner in China, delivering exceptional precision and speed for global clients. We specialize in transforming concepts into tangible, high-quality prototypes efficiently.

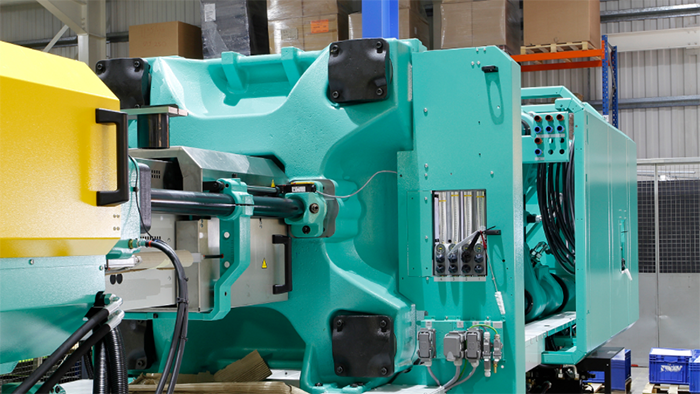

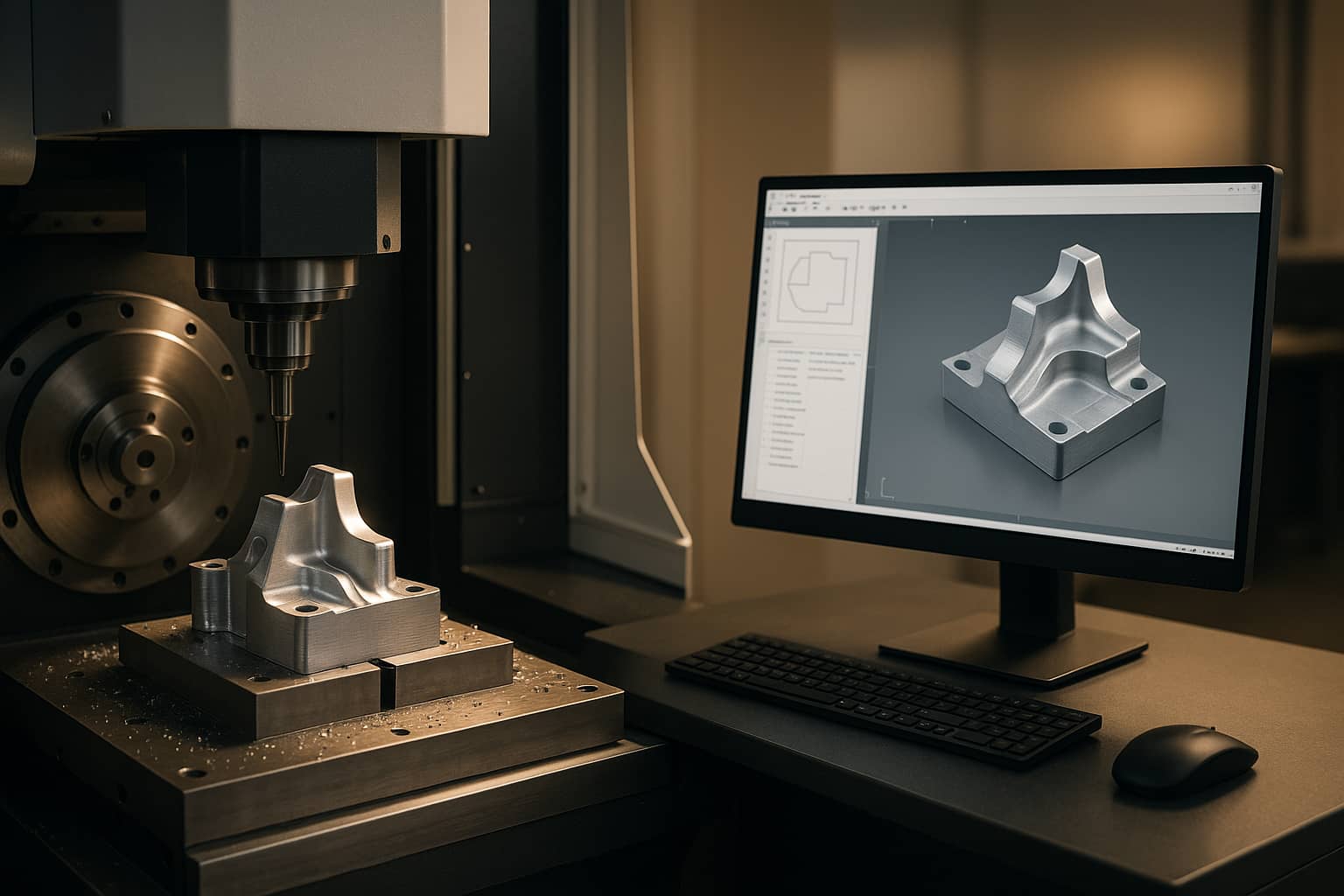

Our sheet metal prototyping services encompass cutting, bending, and assembling with unmatched accuracy. Utilizing state-of-the-art technology and skilled craftsmanship, we ensure every prototype meets rigorous standards. This process is ideal for industries requiring durable and precise components, such as aerospace and automotive.

For businesses in Australia and Europe seeking dependable rapid sheet metal prototyping, Mastars offers a seamless experience. Our expertise reduces lead times significantly, accelerating your time-to-market. Partnering with us means accessing cost-effective solutions without compromising on quality.

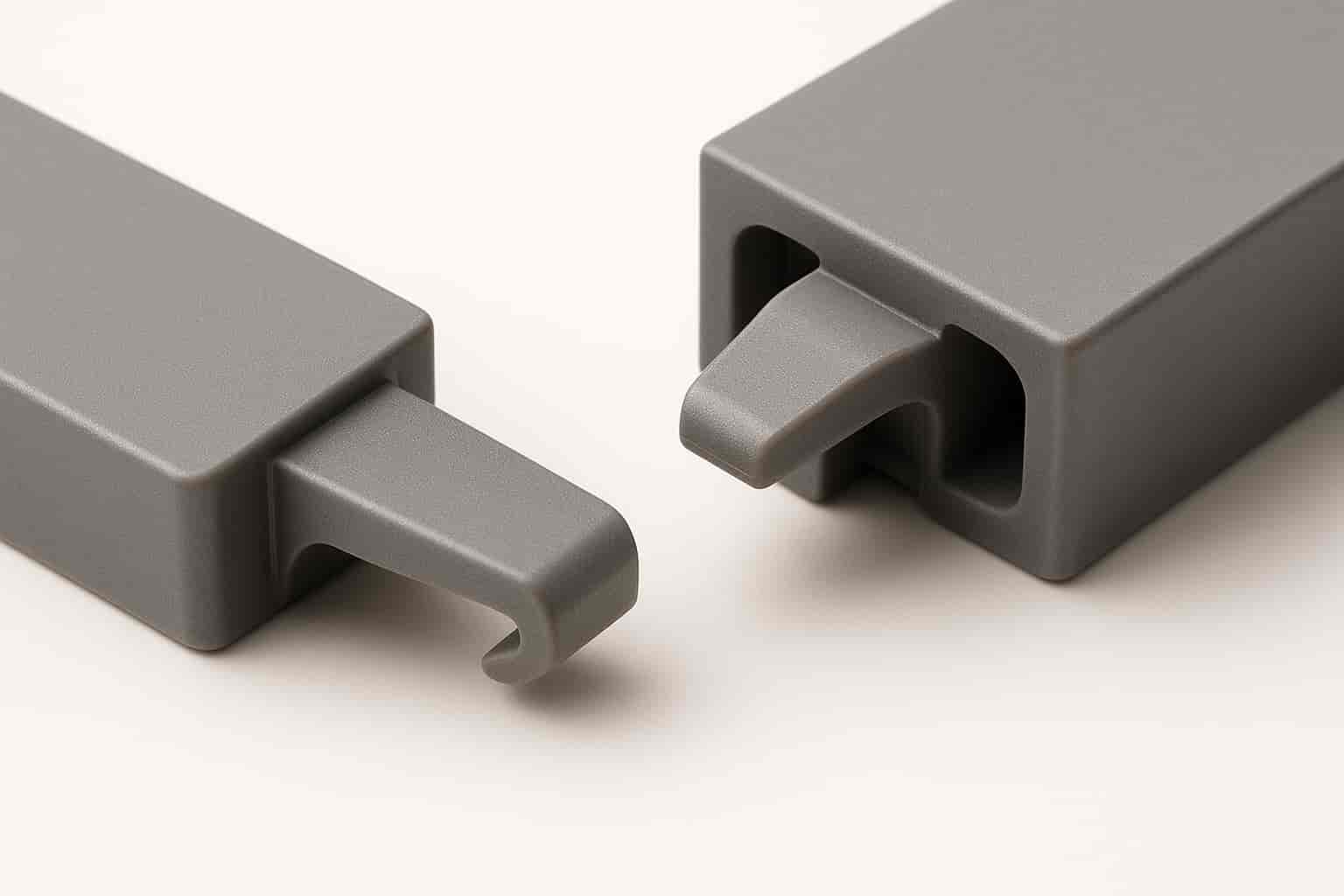

The advantages of custom sheet metal prototyping include design flexibility and material versatility. Clients can choose from various metals, including aluminum and stainless steel, to suit specific project needs. This customization ensures functional prototypes that mirror final production parts.

Understanding sheet metal fabrication design guidelines is essential for successful outcomes. Mastars’ engineering team provides expert guidance to optimize designs for manufacturability and performance. Adhering to these principles minimizes errors and reduces overall costs.

Beyond prototyping, we offer comprehensive low-volume sheet metal manufacturing for pilot runs and initial production. This service bridges the gap between prototyping and full-scale production, ensuring consistency and reliability. It’s perfect for testing market response before committing to large orders.

Why choose Mastars for your sheet metal prototyping needs? Our commitment to quality, affordability, and timely delivery sets us apart. With certifications like ISO 9001, we guarantee processes that meet international standards, giving you peace of mind.

We invite you to experience the Mastars difference in precision sheet metal prototyping. Contact us today to discuss your project requirements and receive a competitive quote. Let us help you bring your innovations to life with efficiency and excellence.