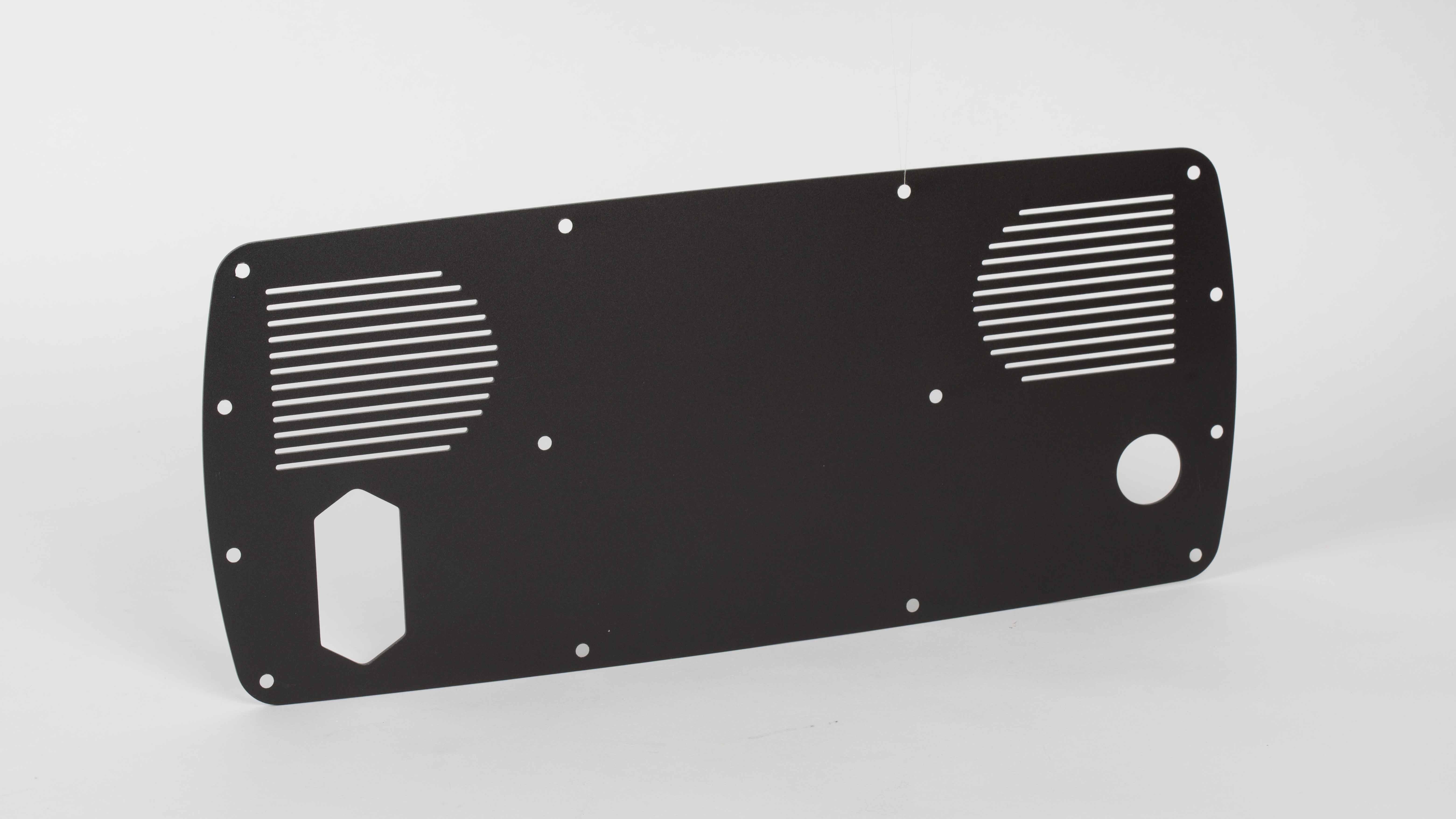

Mastars is a prototype company in China. We employ proven prototype technologies(rapid CNC machining, rapid sheet metal prototyping, vacuum casting prototyping, 3D printing prototyping etc.), to take new concept or design and bring it to life, develop and evaluate new products quickly, economically and with less risk.

The improvement of machining accuracy of mechanical parts effectively ensures the safety, stability and reliability of parts quality and the smooth operation of mechanical equipment.

Ways and methods to improve the accuracy of parts

1. The improvement of grinding process can improve the machining accuracy of parts

The machining level of a country is mainly reflected through the grinding process, in which grinding is the key step and the difficulty in machining. Only by constantly upgrading and improving the processing technology can we improve the quality and accuracy of machined parts and bring more benefits to enterprises.

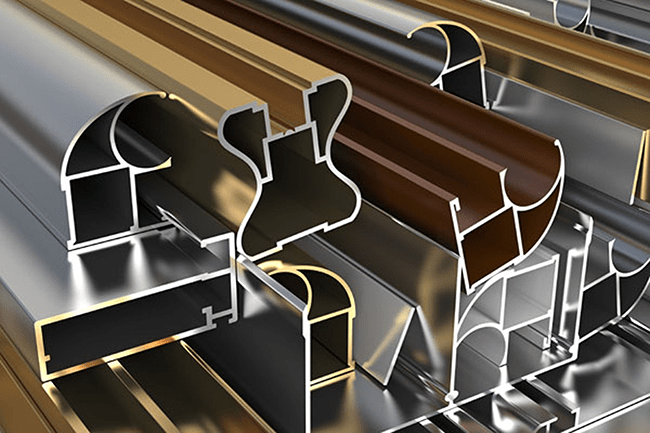

2. Upgrade parts processing equipment

Improving part processing accuracy is inseparable from part processing equipment with high technical level. Upgrading the current part processing equipment can ensure the accuracy and level of part processing from the manufacturer; Higher technology equipment can not only improve the processing accuracy of parts, but also greatly improve the efficiency and quality of parts processing, and promote the scientific and technological content and level of the overall machining and manufacturing industry.

3. Reduce the influence of temperature change on machining accuracy

Temperature control is very important for the machining process. Too high or too low temperature will have a serious impact on the accuracy of parts; By strictly controlling the temperature in the machining process and improving the accuracy of temperature measurement, we can ensure the temperature requirements of parts in the machining process.

4. Change the traditional machining methods and improve the machining accuracy of parts

Introduce advanced processing technology and equipment, upgrade and transform the existing machining technology, and improve the quality and accuracy of parts; At the same time, pay attention to the training of machining operators, constantly improve the technology and ability of operators, ensure that operators can skillfully operate machining equipment and reduce the degree of mechanical damage.

As a modern manufacturer of precision mechanical parts, with CNC processing as the core process, it has physical factories and testing equipment, and integrates supporting manufacturing resources such as rapid prototyping, mold and post-treatment to provide customers with rapid proofing, small and medium-sized batch production, manufacturing and trial assembly, so as to truly achieve a one-stop service that saves worry and effort; The enterprise has imported computer gongs, milling machines, lathes, grinders and other precision machining equipment from Taiwan, as well as a technical team with rich experience in non-standard production.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China