How to Manufacture Plastic Products?

Products made of plastics are part of our daily life. Their presence can be seen everywhere we go like in school, at work in our offices, and especially in our home. We know how to use different shapes and forms of plastic products but do you know what are the different types of plastics and how to manufacture plastic products? Read until the end because this article will give you information about plastics and you will learn some tips for better manufacturing plastic products.

Plastic products can be seen everywhere in daily life. Different plastic products are made through different processing processes. Plastic processing is the process of making plastic into semi-finished products or products with practical value. This usually includes primary processing and secondary processing of plastics.

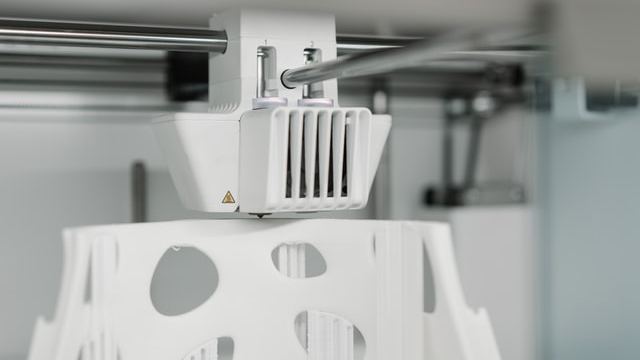

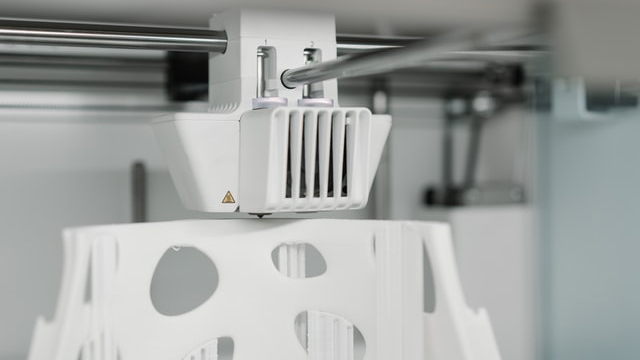

Plastic Injection Molding

This plastic processing method is the most common method. The main steps of this method are

Mold closing → filling → pressure maintaining → cooling → mold opening → demoulding, take out plastic products, and then cycle according to the above steps in the next cycle.

Generally speaking, there are five elements to pay attention to in this method, namely:

1. Temperature: barrel temperature, material temperature, mold temperature, drying temperature, oil temperature, ambient temperature, etc

2. Pressure: injection pressure, holding pressure, back pressure, demoulding pressure, mold opening pressure, mold locking pressure, etc

3. Time: injection time, holding time, cooling time, drying time, metering delay time, etc

4. Speed: injection speed, return speed, mold opening and closing speed, demoulding speed, etc

5. Position: metering position, ejection position, mold opening position, etc

Reaction Injection Molding (RIM)

RMI is the best manufacturing process in producing hard plastic parts. It is commonly used by automotive industries in creating plastic parts of a vehicle like bumpers, stepping boards, and dashboards. It undergoes a chemical reaction inside the mold using thermosetting plastic so it will expand. The plastic part takes in its final form after the chemical reaction is being complete. This can be the most expensive one because of the materials being used and the intensive complex labor applied.

Injection Blow Molding

This method is to extrude the thermoplastic from the head of the extruder to make it into a thin tube, which is called parison, then close the mold, blow air and then form. This method is used more and more widely. For example, in the automotive industry, the materials used are also moving from traditional PE, PP, PVC, pet to high-performance engineering plastics.

Extrusion Blow Molding

The thermoplastic is heated and pressurized in the extruder, and then extruded with a screw. The section shape of the extruded product depends on the machine head, which can be rod-shaped, tubular, flat, different shapes, etc.

Vacuum Casting

This molding method is also called pouring molding. The principle is to inject the liquid plastic with curing agent into the open mold, make it flow to the mold surface, and dry it under atmospheric pressure to complete the polymerization reaction.

Rotational Molding

The principle of rotational molding is to inject powdery or liquid molding materials at room temperature into the rotational molding mold, use heating and centrifugal force to make the plastic evenly distributed on the mold wall, and then get hollow molding products after cooling. This method is suitable for the molding of large articles, but the disadvantage is that the wall thickness is difficult to control.

Mastars Industries CO., LTD

www.mastars.com

Email:

marketing@mastars.com

Tel: +86

755-88210689

Fax: +86

755-8821 0685

Add: Building

6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City,

Guangdong, China